Polyurea coatings are a game-changer for garage floors. They offer unmatched durability, quick installation, and chemical resistance, making your garage floor tougher and easier to maintain. Unlike epoxy, polyurea lasts longer (up to 25+ years), cures in just 24 hours, and resists damage from oil, salt, and temperature changes. Plus, you can customize the look with colors, decorative chips, and UV-resistant finishes that stay vibrant over time.

Key Benefits:

- Durability: Resists cracking, peeling, and impacts better than epoxy.

- Chemical Resistance: Shields against oil, gasoline, and salt spills.

- Quick Installation: Ready for use in just one day.

- Customizable Designs: Choose colors, finishes, and chip blends.

- Low Maintenance: Easy to clean and rarely needs recoating.

For the best results, professional installation ensures proper bonding and long-lasting performance, especially in extreme climates. While the upfront cost is higher than epoxy, the long-term savings and durability make it a smart investment for homeowners across the U.S.

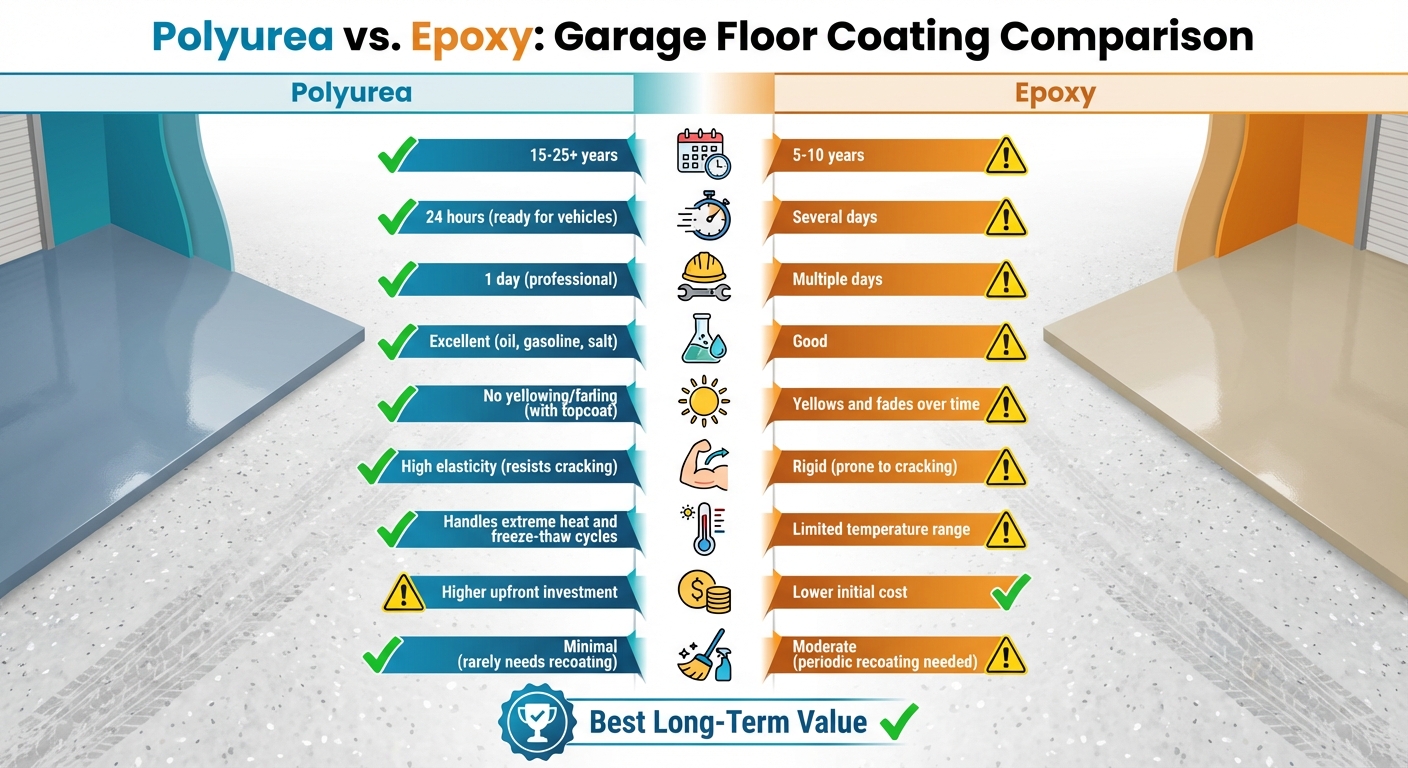

Polyurea vs Epoxy Garage Floor Coating Comparison

Polyurea vs. Epoxy – This Changed Everything for Garage Floors

Why Polyurea Works Well for Garage Floors

Polyurea bonds chemically with your concrete slab, creating a seamless, non-porous layer that keeps moisture, chemicals, and contaminants out while handling temperature changes with ease. This makes it a tough, reliable choice for garage floors, capable of enduring everything from freezing winters to scorching summers. Let’s dive into the specific benefits that make polyurea stand out.

Durability and Flexibility

Thanks to its elasticity, polyurea resists cracking caused by temperature shifts and absorbs the everyday wear and tear of a busy garage. Unlike rigid coatings that may fail as concrete expands in heat or contracts in cold, polyurea stretches and bounces back, maintaining its strong bond with the concrete slab. This flexibility also helps it handle impacts from tools, storage items, and vehicle traffic, offering a level of durability that outperforms standard coatings.

Resistance to Chemicals and Moisture

Polyurea acts as a shield against chemicals and moisture. Spills like motor oil, gasoline, brake fluid, or even road salt stay on the surface, making cleanup a simple task – just wipe it away with a damp cloth and mild cleaner. Its waterproof barrier also prevents de-icing salts from damaging the concrete and keeps moisture out, reducing the chances of mold growth. This protective layer not only safeguards your garage floor but also makes maintenance hassle-free.

Quick Curing and Installation

One of polyurea’s standout features is its fast installation process. In just one day, professionals can grind the concrete, fix any cracks, apply a base coat (often with decorative chips), and finish with a UV-stable topcoat. The material starts curing within minutes and hardens quickly, allowing foot traffic in just a few hours and vehicle parking within 24 hours. This rapid turnaround minimizes downtime, keeping your garage functional without delay. These practical benefits lay the groundwork for even more advantages to be explored next.

Main Benefits of Polyurea Garage Coatings

Better Safety and Appearance

Polyurea coatings are designed with safety in mind, offering slip-resistance through textured chip blends and anti-slip additives that maintain traction – even on wet surfaces. Bare concrete can become dangerously slick when dusty or damp, and many DIY epoxy coatings often have a smoother finish, increasing the risk of slips without added grit. On top of that, the bright, reflective finish of polyurea coatings improves visibility in your garage. This makes it easier to spot tools, steps, or stored items, while reducing trip hazards compared to the darker, light-absorbing surface of uncoated concrete.

When combined with a polyaspartic topcoat, polyurea coatings shine in terms of UV stability. They resist color fading and yellowing, even in garages exposed to intense sunlight day after day. Many homeowners have reported that the finish stays vibrant and glossy over the years, unlike traditional epoxy coatings that often amber or fade when subjected to prolonged UV exposure.

With polyurea, you’re not just getting a safer and better-looking garage – you’re also investing in durability that pays off over time.

Low Maintenance and Cost Savings

Polyurea coatings create a non-porous, stain-resistant surface that repels oil, road salt, and spills. Cleaning is a breeze – most messes can be handled with a quick sweep, a leaf blower, or an occasional mop using water and mild cleaners. Thanks to its resistance to abrasions and chemicals, polyurea doesn’t require frequent re-coating or waxing, unlike some paints or lower-grade coatings. Its tough surface can last 15–20 years, significantly cutting down on long-term maintenance costs.

While the initial cost of polyurea is higher compared to DIY epoxy, the savings over time make it a smart investment. Fewer repairs, less downtime, and improved curb appeal all contribute to its value. This combination of durability and low maintenance not only reduces hassle but also adds economic benefits, tying together safety, performance, and long-term savings.

Customizable Designs and Styles

Polyurea coatings don’t just perform well – they also let you customize your garage’s look to match your style. With a wide variety of base colors and vinyl chip blends – ranging from gray and beige to blue or even custom mixes – you can coordinate the coating with your home’s siding, trim, or interior cabinetry. You can also choose different flake sizes and broadcast densities, whether you want a subtle, low-contrast finish that hides dust or a bold, eye-catching design that turns your garage into a standout space. Finish options range from satin to high-gloss, giving you control over the level of light reflection or understated elegance you prefer.

Popular choices like gray, tan, or charcoal chip blends are especially popular for complementing American home exteriors. Companies like Atlas Concrete Coatings even offer curated chip blends tailored to suit home gyms, car storage spaces, or hobby areas. These design options allow you to personalize your garage without compromising the performance benefits, proving that polyurea coatings deliver both style and substance.

sbb-itb-4b4bb37

What U.S. Homeowners Should Know

Why Professional Installation Matters

Polyurea coatings cure in just a few hours, leaving little room for error during application. Without proper surface preparation, issues like peeling, bubbling, or "hot tire" lift can occur. Professional installers take crucial steps to ensure durability, such as using industrial grinders or shot blasters to open the concrete’s pores, repairing cracks and spalling, and testing for moisture problems before applying the first coat. This meticulous surface preparation creates a much stronger bond than DIY methods like acid etching.

When hiring, look for contractors who specialize in polyurea or polyaspartic systems rather than general epoxy installers. Review their work through before-and-after photos, local customer feedback, and warranty details. For example, Atlas Concrete Coatings offers one-day polyurea chip system installations with warranties of 10–20+ years. A properly installed polyurea system delivers consistent performance across different climates, which is especially important for homeowners across the U.S.

Climate and Regional Performance

Polyurea coatings are designed to handle the diverse weather conditions found throughout the United States. In colder areas like Minnesota and the Upper Midwest, their flexibility allows them to expand and contract with the concrete during freeze-thaw cycles, reducing the risk of cracking or debonding. They’re also resistant to road salt, de-icing chemicals, and automotive fluids that often end up in garages during winter.

In hot and sunny regions like the Southwest and Southeast, polyurea systems with a polyaspartic or UV-stable topcoat maintain their appearance without yellowing or chalking, even under prolonged heat exposure. Another advantage is that polyurea can be installed over a broader temperature range than traditional epoxy, allowing projects to be completed during more months of the year. For humid or coastal areas, installers often perform moisture tests and may use moisture-resistant primers to avoid bubbling or delamination. Older or heavily damaged concrete slabs may require additional repairs and joint filling to ensure the coating can handle minor movements without revealing structural flaws. These attributes make polyurea a dependable choice across various U.S. climates.

Understanding the Cost and Value

Polyurea systems installed by professionals typically cost more upfront than epoxy or concrete paint. This is because they use industrial-grade materials, involve thorough surface preparation, include crack repairs, and require multiple coats. However, this higher initial investment pays off with a lifespan of 15–25+ years and minimal maintenance, compared to epoxy coatings, which often last only 5–10 years.

"An investment in the right protective coating for your garage floor or commercial workspace equals long-term savings and reliable surface performance." – Atlas Concrete Coatings

Polyurea’s resistance to abrasions, chemicals, hot tires, and moisture means it rarely needs recoating. It also protects the concrete slab from damage caused by oil, salt, and moisture, potentially delaying expensive repairs or replacements. When evaluating quotes, don’t just focus on the price. Ask about the scope of surface prep, the number of coats included, whether a UV-stable topcoat is part of the system, and the warranty terms. A cheaper quote that skips essential prep work or uses a thinner, single-coat system might seem appealing at first but can lead to premature failure, ultimately costing more in the long run.

Conclusion

Polyurea coatings stand out for their durability and long-lasting performance, resisting scratches, chemicals, impacts, UV rays, and extreme temperatures for up to 20 years. Its flexibility allows it to adapt to the natural expansion and contraction of concrete during freeze-thaw cycles or intense summer heat. This adaptability helps prevent the cracking and peeling that often plague other coating options.

Beyond its toughness, polyurea delivers practical, everyday advantages. Its quick curing process lets you reclaim full use of your garage in just one day. Plus, its chemical-resistant, low-maintenance surface is easy to clean and comes in a variety of customizable colors to match your personal style.

"An investment in the right protective coating for your garage floor or commercial workspace equals long-term savings and reliable surface performance." – Atlas Concrete Coatings

For the best results, professional installation is essential. Atlas Concrete Coatings ensures a seamless, one-day polyurea application with expert surface preparation and top-quality materials, tailored to withstand the unique challenges of various U.S. climates.

FAQs

What makes polyurea a better choice than epoxy for garage floors?

Polyurea is an excellent choice for garage floors thanks to its long-lasting durability, versatility, and ability to withstand wear and tear. Unlike epoxy, which is prone to chipping, peeling, or fading over time, polyurea holds up its appearance and functionality for the long haul. Plus, it cures much faster, which means installation is quicker and less disruptive.

For homeowners aiming to design a garage that’s both stylish and built to endure heavy use and tough conditions, polyurea provides a dependable, low-maintenance flooring option.

How are polyurea coatings applied to garage floors?

The process of applying polyurea coatings kicks off with meticulous surface preparation. This involves cleaning the surface, fixing any cracks, and making sure the floor is completely dry. Depending on the condition of the surface, a primer might be applied to improve adhesion. Once the surface is ready, the polyurea coating is either sprayed or rolled on in layers, resulting in a smooth, seamless, and tough finish.

A major advantage of polyurea is its fast curing time. It typically dries in just a few hours, meaning your garage could be ready for use the very same day. This streamlined process delivers a durable, professional-grade finish that can transform your space efficiently.

Why should polyurea coatings be professionally installed?

When it comes to applying polyurea coatings, professional installation makes all the difference. Trained experts have the right tools and know-how to deliver a flawless, even finish while steering clear of common issues like peeling, bubbling, or uneven curing.

Beyond aesthetics, professionals ensure the coating maximizes its durability, flexibility, and resistance to wear. This means your garage floor stays not only visually appealing but also tough and reliable for years down the road.