Polyurea coatings are a game-changer for pool deck safety. They create a textured, slip-resistant surface that performs well even when wet, meeting and exceeding safety standards. Unlike untreated concrete, which becomes dangerously slick with water, polyurea offers reliable grip, resists UV damage, and stands up to pool chemicals like chlorine and salt. With a lifespan of over 15 years, it outlasts alternatives like epoxy and paint, making it a durable and low-maintenance solution.

Key Benefits:

- Slip Resistance: Provides strong traction, even in wet conditions.

- Durability: Lasts 15+ years, far longer than epoxy or paint.

- Weather & Chemical Resistance: Handles UV rays, chlorine, and salt without fading or cracking.

- Quick Installation: Ready for use in just 24 hours.

- Customizable Texture: Options for added grip and comfort.

Polyurea is the clear choice for safer, long-lasting pool decks. Whether you’re upgrading a backyard or commercial space, it ensures protection and peace of mind.

Pool Deck Slip Hazards

Wet Surface Dangers

When concrete is left untreated, it becomes a serious hazard around pools, especially when wet. Its smooth, non-porous nature prevents water from being absorbed or directed away, allowing it to pool on the surface. This creates a slippery film that dramatically increases the likelihood of falls.

"The smooth, non-porous surface of untreated concrete doesn’t allow water to be absorbed or channeled away effectively. Instead, water pools on the surface, creating a slick film that is a perfect recipe for slips and falls." – TSR Concrete Coatings

Adding to the danger, while the surface itself is non-porous, concrete still has tiny pores that trap moisture. This trapped moisture encourages the growth of mold, mildew, and algae – problems that are particularly common around pool decks. These growths make the surface even more slippery. Alarmingly, pool areas are linked to about 25% of all slip-related accidents in residential homes, with children and older adults being the most vulnerable to serious injuries.

And it’s not just the immediate risks – over time, environmental factors take a toll on the concrete, making the hazards even worse.

Damage from Weather and Chemicals

Pool decks endure a constant onslaught from weather, chemicals, and general wear and tear. Chlorine and saltwater, both common in pool environments, gradually eat away at the concrete, causing cracks and uneven surfaces that can easily trip someone. On top of that, prolonged exposure to UV rays weakens the material, fades its appearance, and eventually leads to structural issues like spalling and cracking.

"Exposure to the sun’s UV rays also contributes to fading and weakening of the surface, eventually leading to cracks and spalling that create tripping hazards." – TSR Concrete Coatings

In colder climates, freeze-thaw cycles wreak havoc on the concrete. Water seeps into the surface, freezes, and expands, causing cracks to form. Meanwhile, in warmer regions, the sun’s intense heat can make bare concrete dangerously hot – hot enough to burn bare feet. This forces people to wear shoes, which may lack proper grip on wet surfaces, adding another layer of risk. Over time, weathering and foot traffic wear down any natural texture the concrete might have had, leaving the surface smooth and dangerously slick when wet.

All of these factors highlight the need for a more durable and safer option, such as polyurea coatings, to address these challenges effectively.

Concrete Coatings Installation on Pool Deck

How Polyurea Prevents Slips

Polyurea coatings naturally provide a higher level of friction, offering a reliable grip even in wet conditions.

"Meaning our Polyurea material is not as slippery as concrete, making it safer for you and your guests to walk on." – Tyler Gleckler, Chemist, ArmorThane

This natural friction serves as a solid foundation, which can be further improved with customized textures.

Texture and Grip Features

One of the standout benefits of polyurea coatings is the option to customize the surface texture. Contractors can mix in textured additives – tiny elements that resemble tire treads – directly into the coating. These additives vary in size and material, from fine polymer beads, similar to sugar grains, to coarser options like quartz sand, depending on how much traction is needed.

Textured finishes don’t just improve grip; they also create subtle ridges that help water drain off the surface. For pool decks, a medium texture – using materials like quartz sand or walnut shells – strikes a great balance between slip resistance and barefoot comfort. These thoughtful design choices align with pool safety standards, ensuring the deck offers sufficient friction to prevent slips.

Continuous and Long-Lasting Coverage

Polyurea coatings go beyond just immediate safety improvements – they provide long-term slip resistance across the entire surface.

This material creates a seamless, waterproof layer over the deck, eliminating joints or seams where water could pool or mold might grow. This seamless coverage ensures that the slip-resistant texture remains consistent everywhere.

Thanks to its UV stability and resistance to pool chemicals, polyurea holds up well under constant exposure. Its elastomeric properties allow it to handle temperature changes without cracking or losing its textured grip. While traditional pool deck coatings may only last 3–5 years, polyurea coatings can maintain their slip-resistant qualities for over 15 years. This longevity ensures that the safety measures you install today will continue to protect everyone for years to come.

sbb-itb-4b4bb37

Polyurea vs. Other Pool Deck Coatings

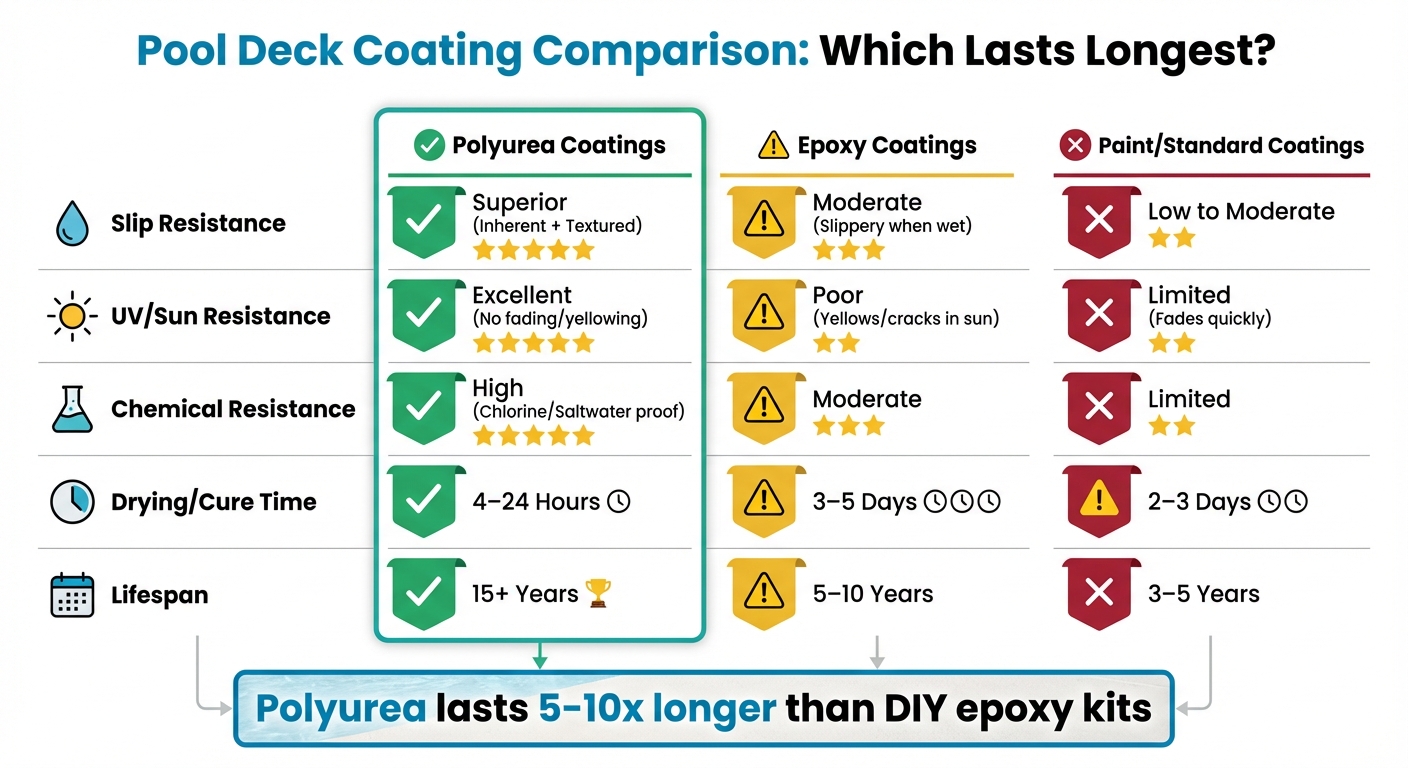

Polyurea vs Epoxy vs Paint Pool Deck Coatings Comparison

When picking a coating for your pool deck, it’s essential to know how different materials hold up in wet, sun-filled environments. Let’s dive into how polyurea stacks up against other options.

Coating Performance Comparison

Here’s a quick look at how polyurea compares to epoxy and standard paint coatings:

| Feature | Polyurea Coatings | Epoxy Coatings | Paint / Standard Coatings |

|---|---|---|---|

| Slip Resistance | Superior (Inherent + Textured) | Moderate (Slippery when wet) | Low to Moderate |

| Sun (UV) Resistance | Excellent (No fading/yellowing) | Poor (Yellows/cracks in sun) | Limited (Fades quickly) |

| Chemical Resistance | High (Chlorine/Saltwater proof) | Moderate | Limited |

| Drying/Cure Time | 4–24 Hours | 3–5 Days | 2–3 Days |

| Lifespan | 15+ Years | 5–10 Years (less outdoors) | 3–5 Years |

Epoxy coatings can become dangerously slippery when wet – exactly the opposite of what you want around a pool. Paint, while inexpensive, offers minimal protection and fades or deteriorates quickly under constant sun exposure. Polyurea, on the other hand, naturally provides better slip resistance (even without additives) and holds up against UV rays without yellowing or cracking.

"Chlorine, saltwater, and cleaning products won’t break down your coating, ensuring long-lasting protection." – FloorTech Concrete Coatings

These features make polyurea a standout choice for anyone looking for a durable, safe pool deck.

Durability and Long-Term Savings

Durability is another area where polyurea shines. While it does come with a higher upfront price tag, its 15–20+ year lifespan far outpaces epoxy (5–10 years) and paint (3–5 years). Over two decades, you’d have to reapply epoxy 4–6 times, incurring repeated material and labor costs.

Polyurea also has a unique flexibility that prevents cracking, even as temperatures shift. This helps avoid trip hazards caused by cracked surfaces and reduces the need for frequent repairs. In fact, polyurea can last 5 to 10 times longer than DIY epoxy kits.

With its durability and performance, polyurea ensures a safer, low-maintenance pool deck that stands the test of time.

Atlas Concrete Coatings Pool Deck Services

When it comes to pool decks, safety is a top priority, and Atlas Concrete Coatings offers a professional polyurea resurfacing system designed to provide exceptional slip resistance. Their approach includes a vinyl chip broadcast that creates a multi-layered textured surface, perfect for wet environments. Enhanced with non-slip additives and supported by a 15-year residential warranty, this solution ensures both safety and durability.

Quick Installation and Stylish Options

The entire installation process is completed in about 24 hours – roughly 70 times faster than traditional epoxy applications. Certified Penntek teams handle the work, ensuring a precise, slip-resistant finish every time.

Atlas Concrete Coatings goes beyond plain gray concrete, offering a variety of finishes to suit different styles. Options include sand tones, Caribbean blues, stone patterns, and metallic effects, all available with glossy or matte topcoats. Their multi-layer system starts with a base coat that penetrates the concrete, followed by a chip layer for added texture and visual appeal, and is sealed with a clear protective topcoat for lasting protection.

"Our chip solution will provide a slip resistant texture along with extra grip." – Atlas Concrete Coatings

This specialized surface also reflects sunlight instead of absorbing it, keeping the deck cooler to the touch compared to standard concrete or darker materials.

Serving Pennsylvania and New Jersey

In addition to its quick application and design flexibility, Atlas Concrete Coatings brings its expertise to homes and businesses throughout Pennsylvania and New Jersey. Their services cover residential and commercial properties, including areas like Bucks County and Montgomery County. Pricing is determined by total square footage and includes preparation, materials, and installation. Whether you’re upgrading a backyard pool deck or resurfacing a large commercial aquatic facility, their team delivers the same attention to slip resistance and durability for projects of any size.

Conclusion

Polyurea coatings bring three standout benefits to pool decks: excellent slip resistance even when wet, longevity that exceeds 15 years, and minimal maintenance while retaining their slip-resistant properties over time. The textured, UV-stable surface is designed to resist fading, cracking, exposure to pool chemicals, and extreme weather conditions. These qualities make polyurea an outstanding choice for enhancing pool deck safety.

Atlas Concrete Coatings provides certified services in Pennsylvania and New Jersey, with a team trained by Penntek. They complete installations in roughly 24 hours, offering a 15-year warranty for added peace of mind. The polyurea system forms a permanent bond with concrete, creating a slip-resistant texture that also reflects sunlight – helping to keep the surface cooler underfoot.

With more than 10 million private pools across the U.S., ensuring a safe pool deck is a priority. Opting for polyurea is a smart step toward long-lasting safety and durability. Atlas Concrete Coatings transforms pool decks into secure, slip-resistant spaces, delivering both safety and value that lasts.

FAQs

How does polyurea make pool decks safer by improving slip resistance?

Polyurea improves slip resistance on pool decks by incorporating textured finishes and anti-slip additives like silica sand or aluminum oxide. These elements create a surface with enhanced traction, even when wet, helping to minimize the risk of slips and falls.

Untreated concrete, on the other hand, can become dangerously slippery when exposed to water. Polyurea coatings are crafted to address this issue, offering safety while maintaining both durability and an attractive appearance. This makes them a smart option for pool decks where preventing accidents is a priority.

Why are polyurea coatings a better choice than epoxy or paint for pool decks?

Polyurea coatings are a strong option for pool decks due to their impressive durability and ability to handle different conditions. Unlike epoxy or traditional paint, polyurea stands up well to UV rays, chemicals, and the wear caused by heavy foot traffic. Plus, it adapts to temperature changes, helping to prevent cracks or peeling over time.

With a lifespan that can extend 15–20 years or more, polyurea offers dependable protection for wet areas like pool decks. It’s a practical choice for homeowners aiming to improve both the safety and look of their outdoor spaces.

Can polyurea coatings be customized to enhance both safety and style on pool decks?

Polyurea coatings are a fantastic option for pool decks because they can be customized to meet specific needs. For instance, you can add slip-resistant textures like silica sand or aluminum oxide to boost traction in wet areas, making the surface safer. On top of that, decorative chips can be included to create stylish finishes that resemble natural stone or granite, giving your pool deck a distinctive and polished appearance.

These coatings combine practicality with flexibility, offering a way to enhance both safety and visual appeal. Their strength and versatility make them a reliable, long-term choice for crafting outdoor spaces that are both secure and attractive.