Slip-resistant coatings are essential for pool decks to ensure safety, durability, and protection against UV rays and weather damage. Without proper coatings, concrete surfaces can become slippery, crack, fade, and erode over time due to moisture, sunlight, and temperature changes. Here’s what you need to know:

- Slip Resistance: Coatings with textured finishes (using aggregates like quartz or aluminum oxide) reduce accidents on wet surfaces. Many meet OSHA‘s wet condition safety standards.

- UV Protection: UV rays cause fading, chalking, and weakening of unprotected concrete. UV-stable coatings like polyaspartic resist these effects, maintaining color and durability.

- Weather Resistance: Freeze-thaw cycles, rain, and pool water lead to cracking, mold, and efflorescence. High-performance coatings block moisture and prevent damage.

- Heat Reflectivity: Lighter-colored coatings reflect sunlight, keeping surfaces cooler to walk on during hot weather.

- Durability: Options like polyurea and polyaspartic coatings last 10–15+ years, outperforming traditional epoxy.

Proper preparation (cleaning, crack repair, and surface profiling) and application (multi-layer systems with primers and topcoats) are critical for long-lasting results. Regular cleaning and resealing every 3–5 years ensure safety and prolong the deck’s lifespan.

Key takeaway: Investing in professional-grade coatings protects your pool deck from wear, reduces maintenance costs, and keeps it safe for years to come.

E-Z Pooldeck Acrylic Coating – Non-Skid Epoxy Fortified Deck Coating (6 Colors & Application Steps)

Why UV and Weather Resistance Matters

Pool decks endure constant exposure to UV rays and harsh weather, which can lead to serious damage if left unprotected. UV rays do more than just fade colors – they break down the chemical structure of coatings, leaving behind a chalky, porous surface that weakens over time. This deterioration doesn’t just affect the deck’s appearance; it also compromises safety, making it clear why protective measures are so important.

How UV Rays Affect Pool Deck Coatings

UV rays are a major culprit in coating degradation, causing surfaces to chalk and crumble into powder. Standard epoxy coatings are especially vulnerable, as they tend to yellow, crack, and become brittle under prolonged sunlight. That’s why polyaspartic topcoats are a game-changer for outdoor pool decks. These coatings have shown impressive UV stability, even after enduring 9,000 hours of weathering tests.

Color retention is another critical factor. Without UV-stable coatings, vibrant pool deck colors can fade into dull tones or develop an unattractive amber tint. Additionally, intense sunlight causes materials to expand and contract. High-quality UV-resistant coatings are designed to handle these temperature shifts without cracking. Many of these coatings also feature breathable technology, which allows moisture trapped inside to escape while blocking external water. This prevents issues like blistering and bubbling.

Common Weather Problems for Pool Deck Surfaces

Weather conditions bring their own set of challenges. In colder climates, water infiltrates porous concrete, freezes, and expands, leading to cracks and uneven surfaces that can create tripping hazards.

Moisture is a year-round concern. Rain and pool water splashing keep surfaces damp, encouraging the growth of mold, mildew, and algae. These biofilms make the surface dangerously slippery. Chlorine and saltwater further complicate matters by eroding unprotected surfaces, leaving behind white, powdery efflorescence – a clear sign that the concrete’s structural integrity is deteriorating. Temperature swings only add to the problem, as materials expand in the heat and contract in the cold. Without flexible coatings, this cycle leads to cracks, surface splitting, and delamination.

To tackle these challenges, high-performance coatings are a must. Atlas Concrete Coatings offers UV-resistant, slip-resistant solutions specifically designed to protect pool decks from these environmental threats, ensuring both safety and durability for years to come.

Key Features of High-Performance Slip-Resistant Coatings

Modern pool deck coatings go beyond aesthetics, offering protection against UV rays, temperature changes, and chemical exposure, all while ensuring dependable slip resistance.

Traction and Safety Features

Slip resistance in these coatings comes from adding materials like polymers, sand, marble dust, or pumice. These additives create a textured surface with tiny irregularities that improve grip, even when wet. This texture not only enhances traction but also helps reduce heat transfer on sunny days. Popular finishes like "orange peel" or knockdown overlays further improve safety by increasing airflow and providing a comfortable surface for bare feet. These textured designs pair well with coatings that focus on UV and heat management, making them a practical choice for busy pool areas.

UV and Heat Reflectivity

One standout feature of advanced coatings is their use of UV-stable resins. Unlike traditional epoxy systems, polyurea and polyaspartic formulations resist yellowing and chalking, maintaining their color and durability even after prolonged exposure to sunlight. Heat reflectivity is another key advantage, achieved through light-reflective pigments that deflect sunlight. Lighter shades like beige, sand, or white stay cooler compared to darker tones. Additionally, the microtextured surface improves airflow, further reducing heat buildup. Combined with effective waterproofing, these coatings are built to handle the challenges of outdoor environments.

Waterproofing and Chemical Resistance

Pool decks are constantly exposed to harsh chemicals like chlorine, saltwater, algaecides, and mineral oils. High-performance coatings act as a protective barrier, preventing these substances from penetrating and damaging the concrete. Polyurea coatings, known for their elastomeric flexibility, can expand and contract with temperature changes without cracking, providing a lifespan of 10 to 15 years.

Atlas Concrete Coatings offers polyurea systems that combine UV stability, chemical resistance, and slip resistance, making pool deck refurbishment quick and effective. These systems often start with an epoxy primer for moisture vapor control, followed by a polyaspartic topcoat to enhance durability against UV exposure and chemicals. This multi-layer design ensures your pool deck remains protected and functional for years to come.

Types of Slip-Resistant Coating Technologies

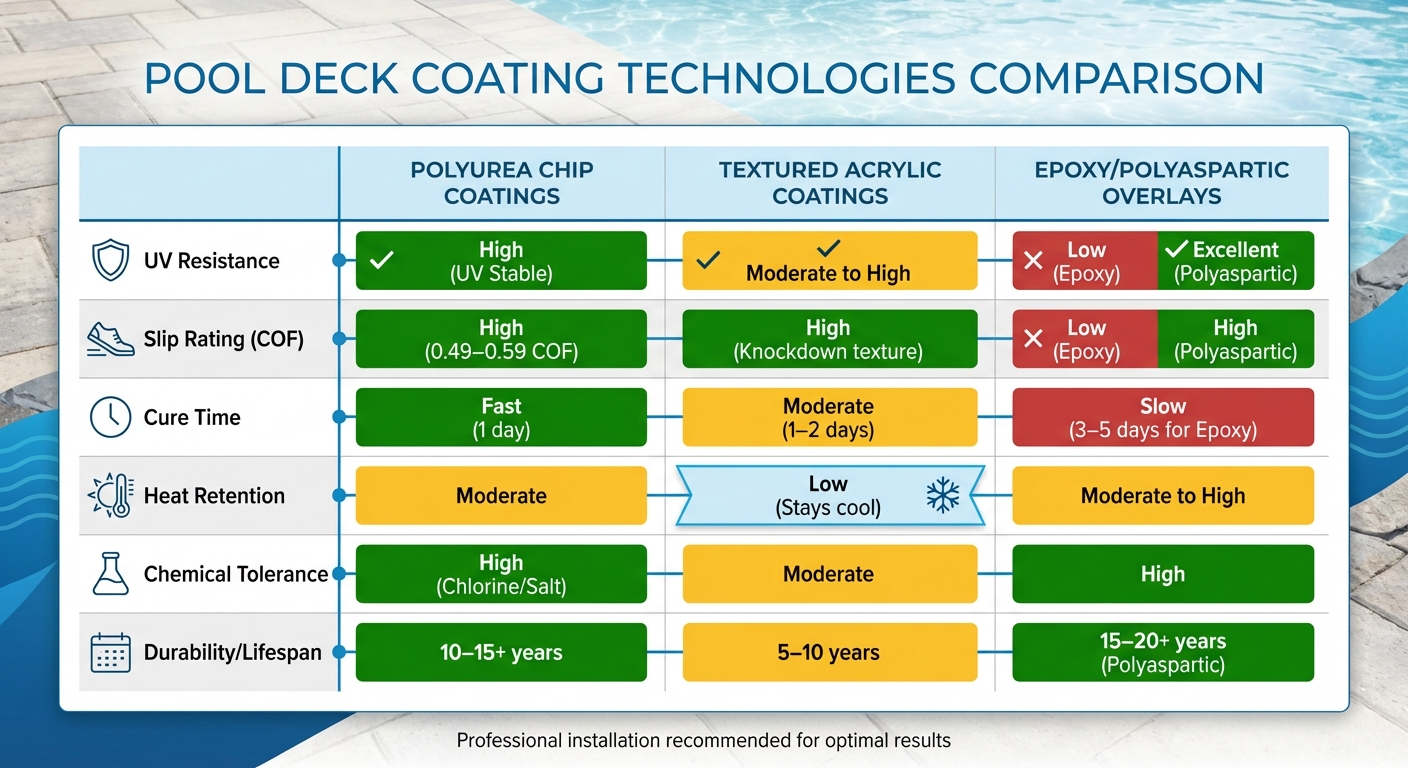

Pool Deck Coating Technologies Comparison: UV Resistance, Durability and Safety Features

Choosing the right slip-resistant coating depends on factors like UV protection, curing time, and durability. Each option has its strengths when it comes to handling sunlight and weather exposure.

Polyurea Chip Coatings

Polyurea coatings are known for their UV stability and flexibility, making them a great choice for outdoor areas exposed to the elements year-round. These systems use an elastomeric formula that adapts to concrete’s expansion and contraction during freeze-thaw cycles, helping to prevent cracking – an issue common with more rigid materials. Decorative chips embedded in the coating improve both slip resistance and visual appeal. Installation and curing are quick, often completed in just one day, compared to the 3 to 5 days needed for traditional epoxy systems. Experts highlight polyurea’s strong resistance to wear, UV rays, and temperature fluctuations. Companies like Atlas Concrete Coatings use polyurea-based systems to deliver long-lasting results, with a lifespan of 10 to 15 years or more.

For those prioritizing heat management, textured acrylic coatings offer an alternative worth considering.

Textured Acrylic Coatings

Often referred to as "cool deck" finishes, textured acrylic coatings are cementitious overlays combined with acrylic resins. Their standout feature is heat management, as they remain cooler underfoot in direct sunlight compared to other options. Spray-applied textures enhance both safety and comfort. John Reynolds, a Brickform Technical Expert, explains:

Cementitious coatings like Cem-Coat Plus are the go-to solution for complete pool deck makeovers. They give you so many options for color, allowing worn-out surfaces to be transformed into beautiful, long-lasting finishes.

While acrylic coatings provide moderate to high UV resistance and maintain color well, they typically fall short of polyurea or polyaspartic systems in terms of chemical durability.

Epoxy and Polyaspartic Overlays

Epoxy coatings are excellent for creating moisture barriers and withstanding heavy traffic, but they have a major drawback: they yellow, chalk, and crack when exposed to UV light. This makes standard epoxy unsuitable as a topcoat for outdoor pool decks. Polyaspartic coatings address this issue by offering UV stability, ensuring they retain their finish without fading or discoloring under intense sunlight. The best approach combines the strengths of both materials: an epoxy primer to manage moisture from porous concrete, followed by a polyaspartic topcoat for UV protection. Polyaspartic systems also deliver a coefficient of friction between 0.49 and 0.59, exceeding OSHA’s national standard of 0.42 for slip-resistant flooring. Floor Shield Coatings emphasizes the importance of this combination:

A UV-resistant topcoat, like a polyaspartic, is crucial to protect your pool deck from fading and deterioration.

The table below highlights the main differences between these coating technologies.

Technology Comparison

| Feature | Polyurea Chip Coatings | Textured Acrylic Coatings | Epoxy/Polyaspartic Overlays |

|---|---|---|---|

| UV Resistance | High (UV Stable) | Moderate to High | Low (Epoxy) / Excellent (Polyaspartic) |

| Slip Rating | High (0.49–0.59 COF) | High (Knockdown texture) | Low (Epoxy) / High (Polyaspartic) |

| Cure Time | Fast (1 day) | Moderate (1–2 days) | Slow (3–5 days for Epoxy) |

| Heat Retention | Moderate | Low (Stays cool) | Moderate to High |

| Chemical Tolerance | High (Chlorine/Salt) | Moderate | High |

| Durability | 10–15+ years | 5–10 years | 15–20+ years (Polyaspartic) |

sbb-itb-4b4bb37

How to Prepare and Apply Slip-Resistant Coatings

Creating durable pool deck coatings starts with proper preparation. Skipping steps or rushing through can lead to issues like peeling, bubbling, or early wear. The key to a professional finish lies in how well the surface is prepped before the first coat goes on.

Surface Preparation Steps

Start by thoroughly cleaning the surface with a pressure washer to eliminate dirt, debris, and algae. For oil stains, use a degreaser, and tackle mold or mildew with a bleach-water solution and a stiff brush. Once the deck is clean, inspect it for cracks or damage. Fill any imperfections with a flexible epoxy filler or patching compound to create a smooth, even surface. High ridges or uneven areas should be ground down to ensure uniformity.

To help the coating bond, the surface needs profiling. This can be done by etching the concrete with muriatic acid or using mechanical grinding to open its pores. After etching, the surface should feel like fine-grit sandpaper. Safety is critical when working with muriatic acid – wear rubber gloves, boots, and a respirator to protect yourself from harmful fumes. Make sure the deck is completely dry before moving forward, as moisture trapped beneath the coating can lead to peeling or bubbling. For highly porous concrete, applying an epoxy primer can act as a moisture barrier.

Before starting the application, tape off adjacent areas and cover the pool water to prevent contamination. The best conditions for applying coatings are temperatures between 50°F and 85°F with low humidity. Avoid working in direct sunlight, as it can cause the coating to dry too fast, affecting the finish.

Once the surface is prepped and dry, you’re ready to move on to the application process.

Application Process for Professional Results

A multi-layer system delivers the best results. Start with an epoxy primer to control moisture, followed by a polyaspartic or polyurea color coat. You can add chips or quartz to this layer for texture. Finish with a UV-stable topcoat to protect against sun damage. Apply the coating from the farthest point, working backward to avoid stepping on wet areas. Use a quality roller to ensure thin, even coats.

For areas with heavy foot traffic, you can boost slip resistance by adding silica sand or quartz granules to the topcoat. Another option is to broadcast aluminum oxide grit over the wet sealer for a stronger, textured finish. These methods ensure the coating remains resistant to UV rays and weather damage.

After application, allow at least 48 hours for the surface to cure before walking on it. In humid conditions, this curing time may need to be extended. Resurfacing a pool deck typically costs between $3 and $5 per square foot, which is more budget-friendly compared to the $6 to $10 per square foot needed for new concrete.

At Atlas Concrete Coatings, we follow these steps meticulously to deliver coatings that enhance safety while elevating the look of your pool deck.

How to Maintain Slip-Resistant Pool Decks

Keeping your pool deck safe and slip-resistant involves regular cleaning and resealing. This not only preserves its UV resistance but also ensures its texture remains effective.

Cleaning and Inspection Guidelines

To maintain your pool deck, start with weekly sweeping using a broom or leaf blower to clear away debris. For deeper cleaning, use a garden hose or a low-pressure washer along with a mild soap solution twice a year. Avoid harsh chemicals, and always rinse thoroughly to prevent residue buildup. If spills like sunscreen, oil, or food occur, clean them up immediately. For oil stains, sprinkle baking soda to absorb the residue before washing with a mild detergent.

Regular inspections are just as important. Check for cracks, peeling, or fading, and address these issues quickly to prevent further damage, such as water intrusion or freeze-thaw cycles. A simple water beading test can help you determine if resealing is needed – if water soaks into the surface instead of beading up, it’s time to reseal.

Resealing and Traction Restoration

After cleaning and inspecting, resealing your pool deck is the next step to ensure lasting protection. For most residential decks, resealing is recommended every 3 to 5 years. However, if your deck experiences heavy foot traffic or harsh weather conditions, or if it’s part of a public or commercial pool area, resealing may be necessary every 1 to 2 years. As Justine Guidry from Concrete Network explains:

Generally, a pool deck should be sealed every 2 to 5 years.

Before applying a new sealant, make sure the deck is completely clean and dry. Use a UV-resistant sealant, such as acrylic or polyurethane, to protect the color and surface. To improve slip resistance, mix grit additives like silica sand or aluminum oxide into the sealant.

Companies like Atlas Concrete Coatings use UV-stable polyurea topcoats that are designed to endure harsh weather while maintaining traction. Resealing costs typically range from $2 to $6 per square foot, making it an affordable way to protect your pool deck and extend its lifespan. Regular resealing not only shields the deck from wear but also keeps it safe and functional for years to come.

Conclusion

Selecting the right slip-resistant coating for your pool deck goes beyond just looks – it’s about ensuring safety, durability, and long-term functionality. Untreated concrete can quickly lose its grip and deteriorate under constant exposure to UV rays, pool chemicals, and extreme weather. On the other hand, high-performance polyurea and polyaspartic coatings provide exceptional traction and durability, lasting three to four times longer than standard surfaces. This highlights the importance of choosing a strong, professionally applied solution.

While DIY kits may seem convenient, they often fall short in outdoor environments. Professional-grade polyurea coatings, however, can outlast DIY options by 5 to 10 times. Companies like Atlas Concrete Coatings prioritize proper surface preparation, use industrial-grade materials, and apply coatings with precision. Their polyurea-based systems are specifically designed to handle harsh UV exposure, resist pool chemicals, and maintain reliable slip resistance even when wet – meeting stringent safety standards.

A professionally installed, UV-resistant coating not only minimizes repair and maintenance expenses but also enhances the safety of your pool area. With routine care and resealing every 3 to 5 years, your pool deck can remain safe and visually appealing for decades. Choosing high-quality materials and expert installation ensures a pool deck that stands the test of time.

FAQs

What advantages do polyurea and polyaspartic coatings offer for pool decks?

Polyurea and polyaspartic coatings bring a range of advantages to pool decks. These coatings are known for their strength, standing up to heavy use and resisting wear over time. Plus, they offer UV protection, helping to keep surfaces from fading or discoloring under the sun. Their ability to handle tough weather conditions makes them a solid choice for outdoor applications.

One standout feature is their quick curing time, which means your pool deck can be back in action faster, reducing downtime. They also improve slip resistance, adding an extra layer of safety to wet areas around the pool. On top of that, these coatings provide a sleek, polished finish that enhances the overall look of your outdoor space. Together, these benefits make them a dependable option for pool deck surfaces.

How do UV rays and weather conditions impact the lifespan of pool deck coatings?

Prolonged exposure to UV rays and harsh weather can take a serious toll on pool deck coatings. Constant sunlight can lead to fading, yellowing, or even cracking of the surface. On top of that, temperature swings, moisture, and rain can cause issues like peeling, surface scaling, or structural damage – especially if the coating isn’t built to handle these challenges.

The key to keeping your pool deck in great shape lies in selecting coatings specifically designed to resist UV damage and weather-related wear. Products like those from Atlas Concrete Coatings are crafted for durability, helping your pool deck stay safe and visually appealing for years.

How can I maintain and reseal my slip-resistant pool deck?

To keep your slip-resistant pool deck in top shape, start with regular cleaning. Sweep it weekly to clear away dirt and debris, and occasionally give it a deep clean to tackle buildup from pool chemicals or other residues. This routine not only helps maintain its appearance but also prevents unnecessary wear.

Make it a habit to inspect the deck often for any cracks, uneven areas, or signs of damage. Fixing these issues early can stop them from getting worse and ensures the surface stays safe for everyone.

When resealing becomes necessary, choose a high-quality, slip-resistant sealer that offers protection against UV rays and weather exposure. To boost traction and extend the deck’s lifespan, consider mixing in materials like silica sand or polymer beads. This step enhances both safety and the overall look of your pool deck.