Polyurea flooring offers a long-lasting, low-maintenance, and eco-conscious solution for homes, businesses, and industrial spaces. With a lifespan of 25–30 years, it outlasts epoxy and vinyl by a wide margin, reducing waste and replacement costs. Its low to zero VOC emissions improve indoor air quality, making it safer for sensitive environments like homes, schools, and hospitals. Additionally, polyurea cures in just 1–4 hours, saving energy during installation and minimizing downtime. Its chemical resistance prevents harmful spills from contaminating soil or groundwater, making it a practical choice for both residential and industrial applications.

Key Benefits:

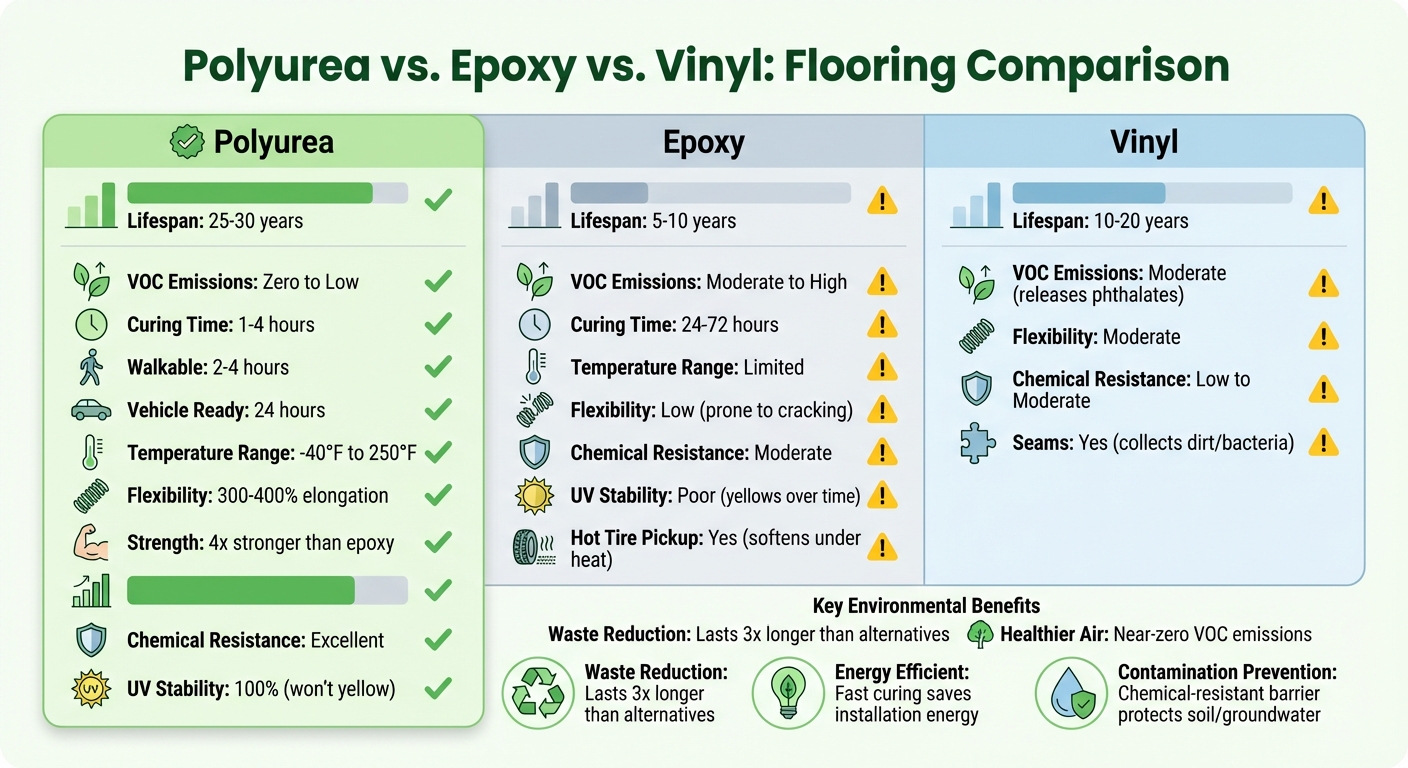

- Durability: Lasts 25–30 years, far exceeding epoxy (5–10 years) and vinyl (10–20 years).

- Low VOC Emissions: Improves indoor air quality and reduces health risks.

- Fast Curing: Ready for use in hours, cutting energy use and downtime.

- Chemical Resistance: Protects against spills and prevents environmental contamination.

- Versatile Applications: Ideal for garages, pool decks, commercial kitchens, and industrial facilities.

Polyurea coatings combine performance and eco-friendly features, making them a smart choice for those prioritizing durability and safety.

Polyurea vs Epoxy vs Vinyl Flooring: Durability and Performance Comparison

Polyurea Concrete Coatings In-Depth: Problems & Benefits

sbb-itb-4b4bb37

How Polyurea Coatings Benefit the Environment

Polyurea coatings stand out for their near-zero VOC emissions and impressive durability, addressing both health concerns and resource efficiency. These qualities make them a smart choice for sustainable flooring. Let’s take a closer look at these benefits.

Low VOC Emissions for Better Air Quality

Traditional flooring materials often release VOCs (volatile organic compounds), which can harm air quality and the environment. In contrast, polyurea coatings are formulated with zero or extremely low VOCs, setting them apart from conventional options like epoxy or vinyl.

Because polyurea is solvent-free, it produces minimal odor during installation. This makes it safe to apply in occupied spaces without the risk of respiratory irritation, headaches, or dizziness commonly linked to epoxy fumes. This feature is especially valuable for sensitive environments like schools, hospitals, or residential areas such as basements.

Additionally, polyurea doesn’t release harmful secondary chemicals like phthalates from vinyl or formaldehyde from laminate flooring. Considering the EPA estimates annual costs from indoor air pollution exceed $100 million, choosing low-VOC flooring options like polyurea has clear health and economic advantages.

Beyond improving air quality, polyurea’s durability also plays a significant role in sustainability.

Long Lifespan Reduces Waste and Resource Consumption

Polyurea coatings last an impressive 25–30 years, far outpacing the durability of epoxy (5–10 years) and vinyl (10–20 years). This extended lifespan means fewer replacements are needed, reducing the demand for raw materials used in manufacturing, transportation, and installation.

Performance Features That Support Eco-Friendly Goals

Polyurea’s benefits for the environment go beyond its low emissions and durability. Its performance traits actively contribute to energy efficiency and help prevent contamination, reinforcing its environmentally friendly credentials.

Fast Curing Time Saves Energy

Polyurea cures in just 1–4 hours, compared to epoxy, which takes 24–72 hours. This quick curing process leads to energy savings during installation. Since polyurea cures effectively in temperatures ranging from −40°F to 250°F and in high humidity, it reduces the need for additional energy-consuming measures like ventilation, heating, or dehumidification.

"Polyurea coating application is an energy-efficient method as well. Polyurea coatings need less energy since they cure rapidly – often in a single day." – Top Coat Concrete Coatings

Within 2–4 hours, the floor becomes walkable, allowing operations to resume with minimal downtime. This quick turnaround not only saves energy but also enhances productivity, all while maintaining excellent chemical resistance.

Chemical Resistance Protects Against Contamination

Polyurea’s tightly packed molecular structure acts as a barrier against oils, acids, solvents, and other harmful chemicals. In the event of spills, this coating prevents contaminants from seeping into concrete and potentially polluting the soil or groundwater. This makes it especially valuable in industrial settings, where secondary containment areas must reliably trap leaks before they cause environmental damage.

Another key feature is its flexibility – polyurea can stretch up to 400% of its original size without cracking. This elasticity prevents cracks from forming, which could otherwise become pathways for contaminants to seep through. As a result, polyurea coatings protect both the structure and the surrounding environment for the duration of their lifespan.

Where Polyurea Coatings Work Best

Polyurea coatings have become a popular choice thanks to their durability, chemical resistance, and quick curing times. Whether it’s a home garage or a demanding industrial facility, polyurea offers a reliable, seamless protective barrier that outperforms many traditional flooring options.

Residential Applications: Garages and Pool Decks

For home garages, polyurea stands out due to its resistance to hot tire pickup – a common issue with epoxy coatings that can soften and peel under high temperatures. Its impressive tensile strength ensures it can handle the weight of vehicles, impacts from dropped tools, and everyday wear without cracking. Plus, since it cures quickly, floors can be ready for use in as little as 24 hours.

When it comes to pool decks and patios, an aliphatic polyurea topcoat is a game-changer. It resists discoloration from sunlight and provides slip resistance, even on wet surfaces. The seamless finish also eliminates grout lines, reducing places where dirt and bacteria can gather, making cleaning much easier. These benefits make polyurea a practical choice for residential spaces while also meeting the demands of commercial and industrial environments.

Commercial and Industrial Applications

In high-traffic commercial settings, flooring needs to withstand constant foot traffic, heavy equipment, and exposure to chemicals. Polyurea delivers with its ability to perform in extreme temperatures, ranging from -40°F to 300°F. This makes it suitable for environments like walk-in freezers, commercial kitchens, and automotive facilities. Its quick curing time allows businesses to resume operations within 24 hours, reducing downtime and potential revenue loss.

For industrial spaces exposed to harsh chemicals like petroleum products, acids, or caustic cleaners, polyurea’s chemical resistance prevents floor degradation and helps avoid environmental contamination. Additionally, it can be applied in high-humidity conditions and at temperatures as low as -20°F, making it a practical option for year-round installation. While polyurea may cost 30–40% more upfront than epoxy, its durability can lead to significant savings over time. For instance, a standard two-car garage could save $3,000–$5,000 over 20 years thanks to its extended lifespan. These features not only enhance functionality but also make polyurea a cost-effective and reliable solution for a wide range of applications.

Why Choose Atlas Concrete Coatings for Eco-Friendly Flooring

Atlas Concrete Coatings combines sustainability with high performance, offering long-lasting polyurea-based flooring solutions for homes, businesses, and industrial spaces across Pennsylvania and New Jersey. Their systems are designed to endure for decades, making them a standout choice for those prioritizing durability and environmental responsibility.

Polyurea-Based Chip Floor Coatings with Lifetime Warranties

Atlas’s chip floor coatings are built to last, with lifespans of 15–20+ years and backed by lifetime warranties. In comparison, traditional epoxy coatings typically last only 5–10 years. These polyurea-based systems are 100% solid and free from ozone-depleting solvents, boasting low to zero VOC emissions to promote healthier indoor air quality.

Each chip system incorporates decorative vinyl chips set into a polyurea basecoat, providing slip resistance ideal for wet areas like pool decks, garages, and commercial kitchens. These floors are 100% UV-stable, ensuring they won’t yellow over time, and their waterproof, chemical-resistant surface can withstand exposure to gasoline, motor oil, and various acids. Polyurea coatings are approximately four times stronger than standard epoxy and offer exceptional flexibility (300% elongation), allowing them to absorb impacts without cracking. These features make them an eco-conscious and durable choice for a wide range of applications.

Fast Installation and Professional Service

Atlas Concrete Coatings delivers on its promise of fast, efficient service with one-day installations. Floors are walkable within 4–8 hours and ready for vehicles in just 24 hours. This quick turnaround is thanks to polyurea’s fast curing properties, which help minimize downtime for businesses and disruptions for homeowners.

To ensure top-notch results, Atlas uses specialized high-pressure spray equipment and professional installation techniques. They also offer free consultations and estimates, helping clients choose finishes that align with their aesthetic preferences and performance needs. With their expertise and commitment to quality, Atlas ensures every project meets the highest standards.

Conclusion: Polyurea as an Eco-Friendly Flooring Solution

Polyurea coatings provide a durable and environmentally conscious flooring option, boasting a lifespan of 25–30 years and emitting minimal VOCs, which enhances indoor air quality and reduces waste.

Its benefits go beyond just durability. The fast curing process means less energy usage and quicker restoration of spaces. Plus, its superior chemical resistance creates a protective barrier that prevents hazardous spills from seeping into the soil or groundwater. This makes it a great option for spaces like garages, industrial facilities, and commercial kitchens.

Another standout feature is its thermal flexibility. With the ability to stretch up to 300% and withstand temperatures ranging from -40°F to 250°F, polyurea handles thermal shifts without cracking. This resilience reduces the need for frequent repairs, cutting down on costs over its 15–20-year service life.

Thanks to these features, polyurea stands out as a smart choice for sustainable flooring. Atlas Concrete Coatings brings these benefits to Pennsylvania and New Jersey, offering one-day installations, lifetime warranties, and professional service to protect both your property and the environment for years to come.

FAQs

How does polyurea flooring contribute to better indoor air quality?

Polyurea flooring stands out as a flooring option that contributes to better indoor air quality. It emits far fewer volatile organic compounds (VOCs) than many traditional flooring materials, making it a safer option for homes and businesses alike.

What’s more, polyurea coatings are incredibly durable and resistant to cracking. This durability helps reduce the buildup of dust, mold, and allergens, which can often accumulate in damaged or porous flooring. With its seamless and easy-to-clean surface, polyurea flooring promotes a cleaner, healthier indoor space.

Why is polyurea considered a sustainable flooring option for industrial spaces?

Polyurea is a smart flooring option for industrial spaces, especially when considering its eco-friendly benefits. One key advantage is its low VOC (volatile organic compound) emissions, which help limit environmental harm during application. Beyond that, its long-lasting durability reduces the need for frequent repairs or replacements, saving resources and cutting down on waste. Plus, polyurea’s resistance to chemicals, UV exposure, and extreme temperatures means less maintenance is required, adding to its efficiency and lifespan. These features combine to make polyurea both a practical and environmentally conscious choice for industrial settings.

How does the fast curing time of polyurea benefit residential and commercial flooring projects?

Polyurea’s quick curing time is a standout feature for both residential and commercial flooring projects. Floors can be ready to use in just 24 to 36 hours, significantly reducing downtime and helping spaces return to normal operations faster.

This rapid turnaround is particularly beneficial for businesses that can’t afford long closures or homeowners aiming to finish renovations swiftly. With polyurea, you enjoy a combination of durability and convenience without compromising on quality.