Polyurea flooring offers a fast-curing, durable, and slip-resistant solution for commercial spaces like hospitals, warehouses, and retail stores. Designed to withstand heavy foot traffic, chemical spills, and extreme temperatures, it outperforms epoxy in strength, flexibility, and longevity. Key benefits include:

- Quick Installation: Walkable in 2-4 hours, fully cured in 24 hours.

- Durability: Tensile strength of 2,500–3,800 psi and resistance to cracking, UV damage, and chemicals.

- Safety: Customizable slip-resistant textures reduce fall risks, even in wet or oily conditions.

- Low Maintenance: Easy to clean, with a lifespan of 15–20+ years.

Atlas Concrete Coatings specializes in tailored polyurea systems, offering decorative finishes and warranties up to a lifetime for select applications. For businesses needing resilient, safe, and efficient flooring, polyurea is a practical long-term investment.

Benefits of Polyurea Flooring for Commercial Spaces

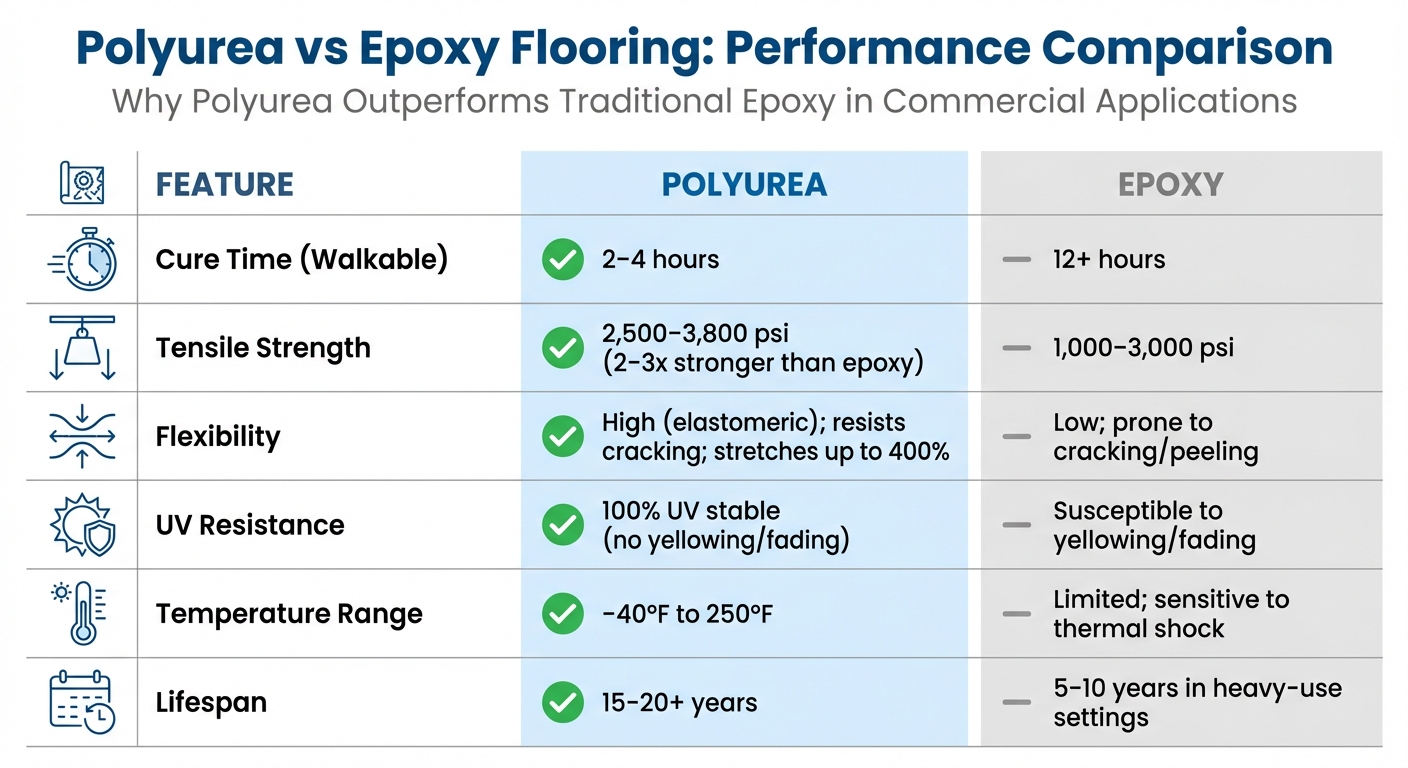

Polyurea vs Epoxy Flooring: Performance Comparison Chart

Fast Curing and Reduced Downtime

In commercial spaces, time is money – polyurea flooring delivers on this front by minimizing downtime. These floors can be walked on within just 2–4 hours of application, a stark contrast to traditional epoxy systems, which require over 12 hours before they’re ready for foot traffic. For businesses like hospitals, grocery stores, or transportation hubs that operate 24/7, this quick turnaround is a game-changer.

Even heavy machinery and vehicle traffic can resume within 24 hours, making polyurea an excellent choice for high-demand environments. However, its rapid curing process requires specialized two-component, high-pressure spray equipment to ensure a flawless application. This combination of speed and strength makes it a reliable option for demanding commercial needs.

Durability and Impact Resistance

Polyurea flooring is built to last, boasting a tensile strength 2 to 3 times greater than standard epoxy floors. While epoxy offers a strength range of 1,000 to 3,000 psi, polyurea takes it up a notch with 2,500 to 3,800 psi.

"With 2 to 3 times the strength of standard epoxy floors, polyurea stands up to the toughest industrial environments with extended service life." – Top Coat Concrete Coatings

What really sets polyurea apart is its elasticity. It can stretch up to 400% of its size without cracking, allowing it to handle temperature swings from –40°F to 250°F without delaminating. This flexibility ensures it remains intact even in extreme conditions, including high humidity levels, where it maintains adhesion at 100% humidity. Some systems even come with 15-year manufacturer warranties, showcasing their long-term reliability.

Slip Resistance and Safety Features

Workplace safety is critical, and polyurea flooring contributes with customizable slip-resistant textures. These finishes provide traction, even on wet or oily surfaces, helping businesses comply with OSHA safety standards and ADA accessibility requirements.

"Polyurea coatings contribute to a safer environment through slip-resistant finishes that provide excellent traction, even in wet or oily conditions." – Keas Concrete Coatings

The level of slip resistance can be tailored to the needs of the space. For example, a commercial kitchen might need a moderate texture to handle water, while an automotive shop would benefit from a more aggressive surface to counteract oil and grease. Additionally, the seamless surface of polyurea flooring eliminates grout lines, reducing areas where bacteria and dirt can accumulate. This makes it an excellent choice for maintaining hygiene in settings like healthcare facilities and restaurants. Combined with its durability and resistance to chemicals, it’s a practical solution for high-traffic environments.

Chemical, Abrasion, and UV Resistance

Polyurea flooring isn’t just about speed and strength – it also holds up against chemical and environmental challenges. From harsh acids and solvents to oils and other substances, polyurea resists them all, making it ideal for automotive shops, manufacturing plants, and other facilities prone to chemical spills.

Another standout feature is its 100% UV stability. This ensures the flooring won’t yellow or fade, even in areas with significant sunlight exposure, such as spaces with large windows or outdoor environments. Its seamless, non-porous surface is also antimicrobial, a crucial feature for infection control in healthcare settings.

| Feature | Polyurea | Epoxy |

|---|---|---|

| Cure Time | 2–4 hours (walkable) | 12+ hours |

| Strength | 2–3x stronger than epoxy | 1,000–3,000 psi |

| Flexibility | High (elastomeric); resists cracking | Low; prone to cracking/peeling |

| UV Resistance | 100% UV stable | Susceptible to yellowing/fading |

| Temperature Range | –40°F to 250°F | Limited; sensitive to thermal shock |

Commercial Applications for Polyurea Slip-Resistant Floors

Retail Stores and Commercial Kitchens

Retail floors endure constant foot traffic and need to look polished at all times. Polyurea flooring offers a range of customizable options, including various colors, flake blends, and metallic finishes, all designed to maintain their appearance over time with 100% UV stability. Plus, it’s four times stronger than traditional epoxy, making it a practical choice for busy retail environments.

In commercial kitchens, where grease, moisture, and chemical cleaning are everyday challenges, polyurea flooring shines. Its seamless, non-porous surface inhibits bacteria and mold growth. Even in greasy or wet conditions, it maintains a high level of friction, reducing the risk of slips. And with the ability to install and cure within just 24 hours, this flooring option minimizes downtime, ensuring food service operations can resume quickly.

But polyurea’s benefits extend well beyond retail and food service spaces.

Warehouses and Manufacturing Facilities

In industrial settings, flooring must handle the weight and movement of heavy machinery, forklifts, and pallet jacks. Polyurea’s durability and resistance to impact and chemicals make it an ideal solution for these demanding environments. Unlike traditional materials, it doesn’t crack or peel under pressure, offering 15–20 years of dependable performance. Companies like Atlas Concrete Coatings customize polyurea systems to meet the specific needs of industrial spaces.

Hospitals and Office Buildings

Healthcare and office spaces have their own unique requirements. In hospitals, where sanitation and air quality are top priorities, polyurea flooring proves invaluable. Its seamless, low-VOC surface eliminates grout lines where pathogens could hide. Additionally, built-in antimicrobial properties actively prevent bacterial growth, a critical feature for infection control.

For office buildings, polyurea provides a surface that’s not just durable but also easy to maintain. A quick mop with a neutral cleaner keeps it looking spotless, making it a practical choice for busy workplaces.

Customization Options with Atlas Concrete Coatings

Polyurea-Based Chip Coatings

Atlas Concrete Coatings provides a chip coating system designed to handle the demands of high-traffic commercial spaces. This system starts with a polyurea basecoat that penetrates deep into the concrete, ensuring a strong bond. A decorative vinyl chip layer is then applied, allowing for custom color matching while creating a natural orange peel texture, which adds slip resistance and extra grip. Finally, a durable topcoat seals the system for long-lasting protection.

"Our chip solution will provide a slip resistant texture along with extra grip." – Atlas Concrete Coatings

This system comes with impressive warranties: a 15-year warranty for residential projects and a lifetime warranty on the chip system’s quality. Plus, the rapid-curing polyurea ensures installation can be completed in just one day, minimizing downtime for businesses. It’s a solution that combines safety, durability, and efficiency, making it ideal for commercial environments.

Slip-Resistant and UV-Resistant Finishes

The topcoat in this system is designed to take durability to the next level. Formulated to resist UV damage, it prevents yellowing or fading, offering complete UV stability for both indoor and outdoor applications. It also stands up to abrasions and chemical spills, maintaining its performance and appearance over time.

For areas that are frequently exposed to moisture or grease – like commercial kitchens or entryways – the finish can be customized with anti-slip additives such as silica sand or aluminum oxide to enhance traction. Certified Atlas installers, trained by Penntek, ensure these finishes are applied correctly for optimal results.

sbb-itb-4b4bb37

Maintenance and Long-Term Performance

After installation, polyurea flooring continues to impress with its low-maintenance needs. Its seamless and non-porous surface naturally resists stains, scratches, and chemical damage from substances like oils, acids, and solvents. Daily upkeep is straightforward – just sweep and mop with standard cleaning products. No need for specialized cleaners or time-consuming maintenance routines.

Polyurea floors boast a lifespan of 15–20+ years, far surpassing epoxy, which typically lasts only 5–10 years in heavy-use commercial settings. This durability is due to polyurea’s unique molecular structure. With 300% elongation, it flexes and absorbs impacts, expanding with the concrete beneath it without cracking.

Over two decades, polyurea requires just one installation, compared to the 4–6 recoating cycles epoxy often needs. This not only reduces long-term costs but also minimizes disruptions. Its impressive strength holds up in extreme temperatures, from -40°F to over 164°F, and it forms a moisture barrier that protects the concrete below from water damage and freeze-thaw cycles.

The slip-resistant texture of polyurea flooring remains effective over time, ensuring consistent safety in areas like commercial kitchens, warehouses, and retail spaces. Its anti-microbial properties and resistance to harsh industrial chemicals – such as petroleum, sodium hydroxide, and sulfuric acid – help maintain both its appearance and functionality.

While polyurea has a higher upfront cost compared to epoxy, its lower total cost of ownership over 20 years, combined with minimal maintenance, makes it an excellent choice for commercial environments where frequent replacements or downtime are not an option.

Conclusion

Polyurea slip-resistant flooring delivers quick curing, long-lasting strength, and improved safety – making it an ideal choice for commercial spaces that can’t afford prolonged downtime or constant repairs. With installation completed in just 24 hours and a lifespan exceeding 20 years, polyurea outperforms traditional flooring options in high-traffic environments. Its durability is further enhanced by advanced surface features designed to boost both safety and resilience.

The seamless, non-porous surface is resistant to chemicals, abrasions, and UV damage. These qualities not only help protect against wear and tear but also minimize workplace injuries caused by slips and falls – a common hazard in commercial settings. Additionally, polyurea flooring supports compliance with safety standards like the ADA, offering peace of mind to facility managers.

Atlas Concrete Coatings specializes in custom polyurea solutions tailored for optimal performance. Their polyurea chip systems are designed to meet both functional needs and aesthetic preferences. With professional installation, they ensure proper adhesion and reliable long-term results across various commercial applications.

Beyond its strength and safety, polyurea flooring safeguards concrete surfaces and reduces overall costs with its built-in moisture barrier and low-maintenance, easy-to-clean finish.

For facility managers looking for a durable, safe, and cost-efficient flooring solution, polyurea stands out as a smart investment. It minimizes downtime, cuts maintenance expenses, and maintains its performance over decades. With Atlas Concrete Coatings’ expertise and tailored options, businesses can implement these high-performance systems effectively, creating safer and more efficient workspaces.

FAQs

What makes polyurea flooring more durable and flexible than epoxy?

Polyurea flooring is known for its long-lasting durability and adaptability, making it a standout option when compared to epoxy. While epoxy floors generally hold up for about 5–10 years under heavy use, polyurea can last an impressive 15–20 years or more, even in tough environments. Its ability to flex with temperature fluctuations helps prevent cracks and other damage over time. On the other hand, epoxy’s rigidity makes it more susceptible to cracking under similar conditions.

Another advantage of polyurea is its superior resistance to UV rays, chemicals, and abrasions. This makes it a perfect fit for outdoor areas, industrial settings, and high-traffic commercial spaces. Thanks to these features, polyurea flooring not only performs well but also retains its appearance, even in challenging environments.

Why is polyurea flooring a safe choice for commercial spaces?

Polyurea flooring stands out as a smart option for commercial spaces thanks to its slip-resistant textures. These surfaces improve traction, even in areas where moisture or spills are common, helping to lower the chances of slips and falls – a crucial benefit for busy environments.

Another advantage is its seamless, non-porous surface, which effectively resists stains, chemicals, and moisture. This not only boosts the flooring’s durability but also makes it easier to maintain a clean and hygienic workspace. Together, these features make polyurea flooring a dependable choice for promoting safety in commercial settings.

How do you maintain polyurea flooring to keep it durable and slip-resistant?

Taking care of polyurea flooring is straightforward and helps preserve its durability and slip resistance over time. Here’s how to keep it in great shape:

- Daily Cleaning: Sweep the floor every day to remove dirt and debris that might scratch the surface.

- Weekly Mopping: Use a microfiber mop and a mild, pH-neutral cleaner once a week to keep the floor spotless and free from stains.

If spills happen, clean them up quickly by blotting the area. While polyurea flooring is resistant to most chemicals, addressing spills promptly can prevent any potential staining. Avoid harsh cleaners or abrasive tools, as they can harm the coating.

For added protection, place mats in high-traffic areas to reduce wear and tear. And if you notice stubborn stains or signs of wear, professional cleaning every few months can help restore the floor’s appearance and maintain its slip-resistant qualities.