Polyurea coatings stand out for their UV resistance, making them ideal for outdoor surfaces exposed to sunlight. This durability is due to their unique chemical structure and the use of aliphatic polyurea formulations, which resist yellowing, fading, and cracking caused by UV radiation. Unlike traditional coatings like epoxy or polyurethane, polyurea maintains its color, gloss, and protective properties over time, even under harsh sunlight.

Key Takeaways:

- UV Damage Prevention: Aliphatic polyurea resists photodegradation, ensuring long-term performance.

- Durability: The coatings don’t crack, peel, or degrade under sun exposure.

- Fast Curing: Polyurea sets in minutes, minimizing downtime during application.

- Moisture Resistance: Performs well even in humid or fluctuating conditions.

- Applications: Ideal for pool decks, patios, driveways, and garage floors.

Polyurea’s advanced formulation includes UV-absorbing additives that neutralize harmful radiation, protecting both the coating and the underlying surface. This makes it a superior choice for maintaining both appearance and structural integrity in outdoor environments.

Polyurea Concrete Coatings In-Depth: Problems & Benefits

How UV Radiation Damages Standard Coatings

Polyurea vs Standard Coatings: UV Resistance Comparison

UV Damage in Epoxy and Polyurethane Coatings

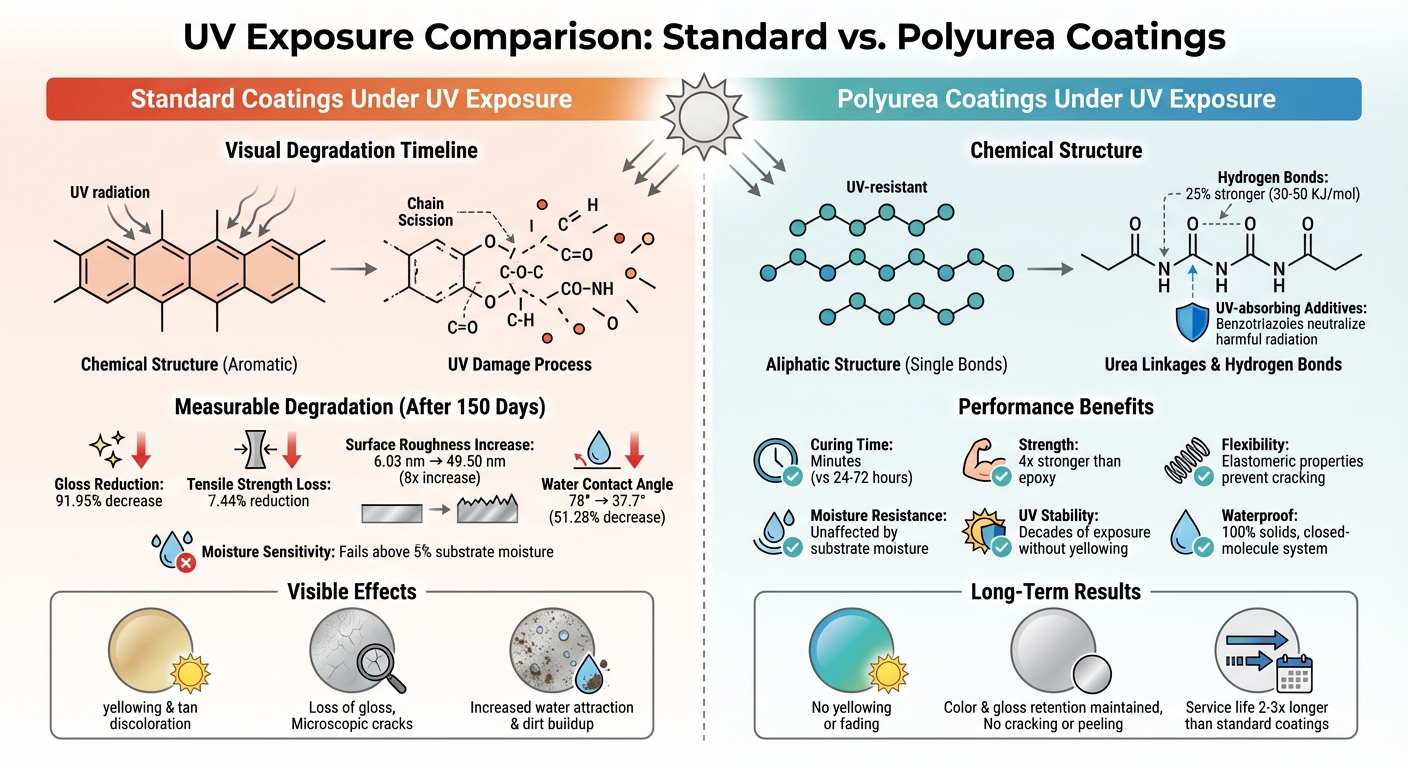

When exposed to sunlight, standard epoxy and polyurethane coatings undergo a destructive chain reaction. UV radiation disrupts key chemical bonds – such as C-O-C, C=O, C-H, and CO-NH – through a process called chain scission. This weakens the coating’s molecular structure from within.

"UV radiation causes polymer chain disruption and, as a result, reduces the gloss of the coating." – Eurasian Chemical Communications

The effects are easy to spot: yellowing, tan discoloration, and a noticeable loss of gloss. Coatings based on aromatic compounds are especially prone to these changes. Over time, prolonged UV exposure not only diminishes gloss and alters color but also causes microscopic cracks to form and expand. These cracks reduce the coating’s ability to protect the surface underneath, like concrete.

UV exposure also makes the coating more hydrophilic, meaning it attracts water more easily. For instance, after 150 days outdoors, the water contact angle of a coating can drop by about 51.28%, from 78° to 37.7°. This increased water attraction encourages dirt buildup and speeds up further degradation. Together, these surface and molecular changes explain why standard coatings struggle to hold up in outdoor environments.

Why Standard Coatings Fail Outdoors

The chemical makeup of standard coatings makes them particularly vulnerable to outdoor conditions. Many polymers absorb solar UV radiation, setting off photothermal and oxidative reactions that break down critical chemical groups. In polyurethane coatings, one common failure point involves the oxidation of the carbon atom located near the nitrogen atom in the urethane group.

Environmental factors like heat and moisture make the situation worse. Cycles of high temperatures and humidity deepen surface cracks and wash away degraded material. For example, in marine environments, just 150 days of natural exposure can lead to a 91.95% reduction in gloss, a 7.44% drop in tensile strength, and an almost eightfold increase in surface roughness – rising from about 6.03 nm to 49.50 nm.

Humidity is another major challenge for polyurethane coatings. If the substrate contains more than 5% moisture, water competes with hydroxyl-polyols in reacting with isocyanate, which often results in adhesion problems and blistering. These factors collectively highlight why standard coatings often fail when exposed to outdoor conditions.

The Science Behind Polyurea’s UV Resistance

Chemical Structure of Polyurea

Polyurea is created through a rapid chemical reaction between isocyanates (the "A" side) and amines (the "B" side), forming durable urea linkages (–NH–CO–NH–) that make up its backbone. This reaction happens in just seconds.

The polymer’s strength comes from alternating hard urea-linkage segments, while its flexibility is provided by soft aliphatic polyethers. These are further stabilized by hydrogen bonds that are 25% stronger than those found in urethane systems, with bond energies ranging from 30 to 50 KJ/mol.

UV resistance in polyurea depends heavily on its chemical composition. Aliphatic polyurea, made with isocyanates containing single bonds (like isophorone diisocyanate), naturally resists UV radiation while maintaining its gloss and color. On the other hand, aromatic polyurea, which contains double bonds, is more susceptible to UV-induced discoloration and gloss loss unless protected by a topcoat. This robust molecular design is key to its UV-resistant properties.

How UV-Absorbing Additives Work

Polyurea’s UV protection is further enhanced with the use of specialized additives. High-energy UV photons can penetrate materials, breaking chemical bonds through a process called photodegradation. This creates reactive free radicals that can trigger a chain reaction, damaging the polymer structure further.

"When photons have enough energy, they can degrade materials through a process known as photodegradation, where photons penetrate objects to break the chemical bonds that hold materials together."

- Tyler Gleckler, Chemist, ArmorThane

UV-absorbing additives, like benzotriazoles, act as a shield. They absorb harmful UV energy and release it as heat, preventing the formation of free radicals and protecting critical N–H and C=O functional groups. This process ensures the coating retains its structural integrity and visual appeal.

Molecular Stability Under Sunlight

Polyurea’s molecular structure is designed to withstand prolonged sunlight exposure. Unlike polyurethane, which relies on catalysts to cure and can be sensitive to moisture (causing blistering at moisture levels above 5%), polyurea is largely unaffected by moisture. The rapid reaction between isocyanates and amines minimizes water interference during curing.

Its microphase-separated structure, with hard segments dispersed among soft ones, balances tensile strength and flexibility, making it resistant to cracking under thermal stress. Additionally, the carbonyl-to-amino hydrogen bonds act as physical cross-links, enhancing the material’s stability during UV exposure.

"Aliphatic polyureas are inherently resistant to UV radiation, and can withstand up to decades of exposure without yellowing or comprising its physical strength."

- ArmorThane

This molecular stability not only preserves the coating’s appearance but also ensures long-lasting performance. When combined with UV-absorbing additives, aliphatic polyurea can maintain its protective qualities and aesthetic appeal for years, even under intense sunlight.

sbb-itb-4b4bb37

Performance Benefits of UV-Resistant Polyurea Coatings

Long-Term Durability Outdoors

UV-resistant polyurea coatings thrive in outdoor environments where standard coatings often fall short. Thanks to their elastomeric properties, these coatings can absorb and disperse impact energy, effectively shielding concrete from damage. Unlike rigid options that crack under stress, polyurea moves with the substrate during temperature changes, avoiding the peeling and cracking issues common with traditional finishes.

Additionally, the coating creates a seamless, waterproof barrier that protects against moisture and corrosion. Its chemical stability ensures it resists molecular breakdown, even under prolonged exposure to sunlight, preventing structural failures.

"The long-lasting nature of polyurea coatings can be attributed to their resistance to environmental factors. They do not crack or peel when exposed to extreme temperatures, and their UV resistance prevents them from fading or degrading under sunlight."

- Classic Coatings & Outdoor Solutions

Another standout feature is its quick curing time. While traditional coatings take 24–72 hours to set, polyurea cures in minutes, making it ready for outdoor use without sacrificing durability.

Color and Gloss Retention

Beyond durability, UV-resistant polyurea coatings excel at maintaining their appearance under sunlight. They resist fading and preserve their original "wet look" finish, even in intense UV conditions. This is a major advantage for outdoor areas where aesthetics matter.

The secret lies in the formulation. UV-resistant polyurea protects polymer chains from photothermal and oxidative reactions, which are the main culprits behind yellowing. It safeguards critical components like the urea linkage (NH–CO–NH) and functional groups such as N-H and C=O from degrading.

For homeowners, this means no unsightly discoloration or dullness that demands frequent recoating. Instead, the coating retains its vibrant color and high-gloss finish year after year, reducing maintenance efforts while keeping outdoor spaces visually appealing.

Best Applications for High-Sunlight Areas

The durability and aesthetic benefits of UV-resistant polyurea make it a top choice for outdoor spaces exposed to constant sunlight. Pool decks and patios are prime examples, as these areas endure harsh weather and direct UV exposure while serving as key parts of outdoor living. Polyurea provides a slip-resistant, waterproof surface that stands up to the elements without fading or degrading.

Driveways also benefit from its impact resistance and ability to handle vehicle weight. The coating withstands hot tire pickup and thermal stress caused by high pavement temperatures during summer.

Garage floors, especially those exposed to sunlight through open doors, gain protection from uneven yellowing and gloss reduction. The coating also resists oil, gasoline, and other automotive fluids, making it a practical choice for high-traffic areas.

| Application | Primary Benefits | Key Protection |

|---|---|---|

| Pool Decks & Patios | Waterproof, slip-resistant, color retention | UV stability, moisture barrier |

| Driveways | Impact resistance, thermal flexibility | Hot tire resistance, no brittleness |

| Garage Floors | Chemical resistance, easy cleaning | Prevents uneven yellowing |

For areas with extreme sun exposure, like unshaded pool decks in southern climates, polyaspartic coatings (a type of aliphatic polyurea) offer unmatched UV stability. These advanced formulations are designed to maintain their properties indefinitely under sunlight, making them the go-to solution for the toughest conditions.

Why Choose Polyurea Coatings from Atlas Concrete Coatings

Polyurea Coating Services

Atlas Concrete Coatings specializes in polyurea-based chip floor systems, designed for outdoor spaces like pool decks, patios, garages, and walkways. Their three-layer system starts with a base coat that penetrates deep into the concrete, followed by a chip layer for added texture and customization. The final layer provides strong UV resistance, ensuring the coating holds up under harsh sunlight.

For outdoor applications, Atlas uses aliphatic polyurea formulas. These are specifically engineered to prevent UV-induced yellowing, making them ideal for areas exposed to intense sunlight. With this approach, patios and pool decks can maintain their vibrant appearance for years.

High-Quality UV-Resistant Materials

Atlas takes pride in using top-tier materials that maximize UV resistance and outperform traditional options. Their polyurea coatings are four times stronger and more flexible than standard epoxy. The 100% solids formula ensures it meets strict VOC standards while delivering excellent durability. Unlike polyurethane, which can be affected by humidity and temperature swings, polyurea is moisture-resistant and cures even in extreme conditions, down to -20°C (-4°F).

The application process involves high-pressure impingement mixing equipment, operating at 150–250 bar (2,175–3,625 psi). This ensures the coating achieves full tensile strength and flexibility. Certified professionals trained by Penntek oversee the installation, preparing surfaces with water jetting or grit blasting to eliminate issues like bugholes or off-gassing.

Benefits of Working with Atlas Concrete Coatings

Atlas doesn’t just offer advanced products; they also deliver a streamlined and efficient experience. Installations are completed within 24 hours, allowing homeowners to use their space immediately. This process is 70 times faster than traditional epoxy applications. Plus, their residential flooring systems come with a 15-year warranty, demonstrating confidence in their materials’ durability and UV resistance.

The polyurea coating forms a permanent bond with the concrete, deeply penetrating its pores. This ensures long-lasting resistance to moisture, chemicals, and abrasions. For outdoor areas like pool decks and driveways, the slip-resistant texture enhances safety, while the UV protection keeps colors vibrant year after year.

Conclusion

Key Points on UV Resistance

Polyurea coatings offer exceptional protection for outdoor surfaces, thanks to their unique molecular structure. By combining rigid urea bonds with flexible polyether segments and incorporating aliphatic isocyanates, these coatings resist UV-induced yellowing and adapt to temperature changes without cracking. This flexibility allows the coating to expand and contract with environmental shifts while maintaining its durability.

The 100% solids formula creates a dense, impermeable barrier that blocks moisture and prevents the growth of algae and bacteria. As Jose Ibarra, Owner of Crown West Inc., explains:

"Being 100 percent solids, it’s a closed-molecule system. It doesn’t bleed, it doesn’t open up, it doesn’t allow for growth of algae and bacteria".

This seamless protection is especially important for outdoor areas like pool decks, patios, and driveways, which endure constant sun exposure. While traditional coatings often degrade under UV radiation, polyurea coatings maintain their color and finish over time. Their rapid curing process, which forms urea linkages in seconds, ensures the coating sets quickly, minimizing the risk of environmental factors affecting its performance. Rob Loomis, Chemist at Willamette Valley Co., highlights the durability:

"Our studies showed that you can increase the service life of the facility two to three times what the current technology was able to provide".

Get Started with Atlas Concrete Coatings

Atlas Concrete Coatings leverages these advanced UV-resistant properties to provide top-tier outdoor surface protection. Their certified installers use aliphatic polyurea formulas designed specifically for outdoor applications in Pennsylvania and New Jersey. Whether it’s pool deck resurfacing, patio coatings, or garage floor solutions, they deliver quick installations paired with a lifetime warranty. Reach out to Atlas Concrete Coatings today for a free consultation and ensure your outdoor surfaces remain protected and visually stunning for years to come.

FAQs

Why are polyurea coatings more resistant to UV damage compared to other materials?

Polyurea coatings are known for their impressive UV resistance, thanks to their unique chemical makeup. The presence of aliphatic compounds in their structure plays a key role in helping these coatings retain their color, gloss, and durability, even after extended exposure to sunlight.

In comparison, other materials such as epoxy or aromatic coatings tend to yellow, fade, or deteriorate when subjected to UV rays. This makes polyurea coatings a reliable option for outdoor applications where maintaining both performance and appearance over time is essential.

What makes polyurea coatings resistant to UV damage?

Polyurea coatings are designed to withstand UV damage, thanks to UV-absorbing additives integrated into their formulation. These additives often include aliphatic compounds, which are known for their stability and resistance to degradation under sunlight. Unlike aromatic compounds, aliphatic compounds help prevent common issues such as fading, yellowing, and pigment deterioration. This ensures the coating retains both its appearance and performance over time.

By leveraging these advanced chemical properties, polyurea coatings provide dependable, long-term protection and maintain their aesthetic quality on surfaces frequently exposed to sunlight.

Why are aliphatic polyurea coatings ideal for outdoor use?

Aliphatic polyurea coatings are a great option for outdoor use thanks to their strong UV resistance. They hold up well under prolonged sunlight, resisting fading, yellowing, or brittleness. This means surfaces treated with these coatings can retain their look and strength, even in tough outdoor environments.

Because of their chemical makeup, they offer dependable, long-lasting performance, making them especially suitable for areas like pool decks, patios, and other outdoor concrete surfaces exposed to constant sunlight.