Outdoor concrete surfaces face constant challenges from the sun’s UV rays, which can cause fading, cracking, and deterioration over time. The solution? Advanced coatings like polyurea and polyaspartic, which outperform traditional epoxy by resisting yellowing, maintaining flexibility, and lasting up to 20 years. These coatings not only protect but also offer stylish finishes for patios, pool decks, and walkways.

Key highlights include:

- Rustic Stone Aesthetic: Hand-carved limestone overlays mimic natural stone with UV-protected finishes.

- Cool-Toned Designs: Light grays and blues reduce surface heat, reflecting sunlight effectively.

- Modern Seamless Finishes: Sleek, solid colors for a contemporary look with long-lasting UV stability.

- Stamped Textures: Patterns like slate, wood, or cobblestone with durable, fade-resistant coloring.

- Garage-to-Patio Transitions: Unified polyurea coatings for indoor-outdoor flow, resistant to cracking and fading.

- Textured Non-Slip Surfaces: Anti-slip additives ensure safety without compromising durability.

Atlas Concrete Coatings specializes in these high-performance systems, ensuring lasting protection and style for outdoor spaces.

Polyaspartic vs Epoxy Coatings: UV Protection and Durability Comparison

Everything You Need to Know About Coating Outdoor Concrete

sbb-itb-4b4bb37

1. Rustic Stone Aesthetic

Combine durability with timeless style using a rustic stone finish that includes built-in UV protection.

Flagstone and Slate Overlays with Hand-Carved Details

Limestone overlays can transform plain concrete into surfaces that look like authentic, quarried stone. Using hand-carved techniques and custom scoring, these overlays create organic patterns that go beyond what stamped designs can achieve. For instance, SunStone demonstrates this approach by replicating materials like flagstone, slate, or travertine through detailed hand-troweling methods.

To preserve these intricate designs, a protective coating is applied, shielding the surface from sun exposure, saltwater, and everyday damage. This ensures the stone-like finish retains its beauty over time. For a natural look, contractors use a mix of integral pigments and water-based stains that penetrate deep into the surface, creating long-lasting, fade-resistant colors.

"The limestone coating overlay that looks and feels like real stone" – SUNDEK

The cost of resurfacing typically ranges from $3 to $10 per square foot. While the hand-carved process may take longer than traditional stamping, the result is a unique surface with the texture and character of real stone – without the hassle of loose pavers or weeds growing between joints.

Atlas Concrete Coatings specializes in installing UV-protected overlays, perfect for enhancing outdoor concrete spaces.

2. Cool-Toned Designs

Create a refreshing and inviting outdoor space by combining light grays, soft blues, and crisp whites.

Light Gray and Blue Blends for Heat Reflection and Visual Comfort

Cool-toned palettes like Silver Creek, Mt. Everest, and Nebula make spaces feel more expansive and serene. These shades also reflect sunlight effectively, helping to reduce surface temperatures. For example, new gray concrete typically has a Solar Reflectance Index (SRI) of 35, while lighter shades like "Ceramic" can achieve an SRI of 71. Increasing the SRI from 35 to the mid-50s can lower surface temperatures by 10–25°F during peak sunlight.

"Light-colored concrete reflects sunlight, helping it stay noticeably cooler in summer heat." – Solomon Colors

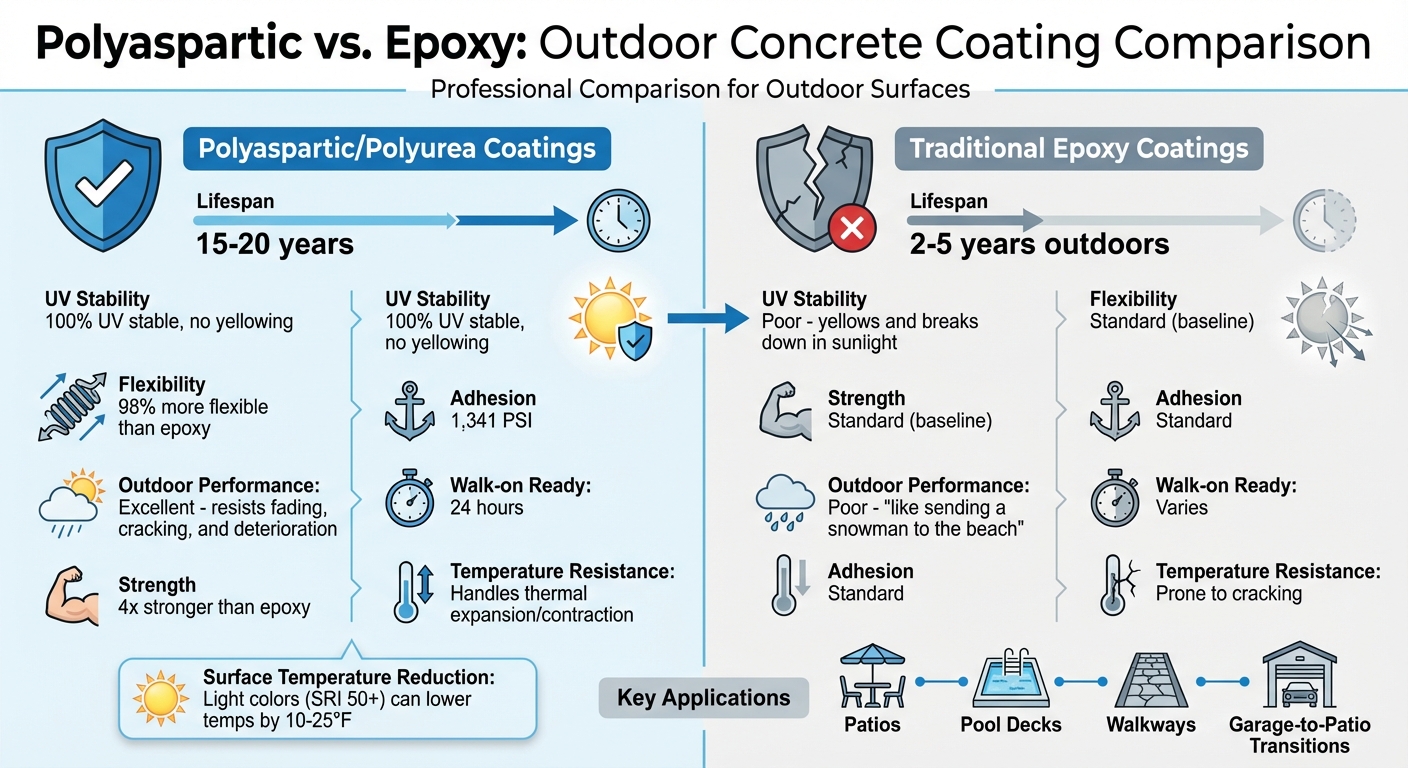

In addition to UV protection, cool-toned designs help minimize heat absorption. For outdoor areas with heavy foot traffic, it’s best to choose colors with an SRI of at least 50. Polyaspartic coatings are ideal for outdoor use since they feature UV-stable pigments that resist yellowing and fading, unlike traditional epoxy systems. These coatings can maintain their color for over 10 years, whereas epoxy systems typically last only 2–5 years.

Blends like Nebula or Nightfall not only add depth to your design but also do a better job of concealing dirt. To ensure the colors work well in your space, always view samples outdoors at different times of day. Keep in mind that north-facing light tends to appear cooler and bluer, while south-facing light has a warmer, golden tone.

Atlas Concrete Coatings specializes in polyaspartic systems that protect and maintain the beauty of cool-toned designs, even under intense UV exposure.

3. Modern Seamless Finishes

Sleek Solid Colors for Contemporary Architecture

Seamless finishes bring a clean, uniform look that perfectly complements contemporary architecture. Solid color options in shades like slate gray, charcoal, or warm taupe are popular choices. These tones provide a subtle, neutral backdrop that pairs beautifully with outdoor furniture while maintaining a sleek, minimalist vibe.

For outdoor applications, UV-stable polyaspartic coatings are the go-to solution. Unlike epoxy, which struggles under outdoor conditions, polyaspartic coatings stay flexible and retain their color for 15–20 years.

"Putting epoxy outdoors is like sending a snowman to the beach." – Galaxy Concrete Coatings Contractor

Achieving this seamless look requires precision. Professionals use a "wet-edge" method during application to avoid lap marks, ensuring a smooth, flawless surface. This approach not only enhances the modern aesthetic but also boosts UV resistance. Adding a high-gloss topcoat further elevates the finish by reflecting natural light, making shaded areas feel brighter and more open. The topcoat also acts as a non-porous barrier, preventing issues like bubbling or peeling.

Atlas Concrete Coatings stands out for its expertise in polyaspartic systems, offering finishes that are both stylish and durable. Their one-day installations deliver impressive adhesion strength – 1,341 PSI – ensuring the finish stays intact even under intense sun exposure.

4. Stamped Textures

Mimicking Natural Materials with UV-Stable Patterns

Stamped concrete offers the look of natural stone, wood, or cobblestone without the upkeep headaches. Using rubber mats molded from real materials, it can recreate textures like slate, flagstone, or wood planks with impressive detail. For a seamless look, texture skins mimic slate, granite, or sandstone without the need for grout lines, creating a smooth, organic surface that’s easier to clean and maintain.

When it comes to outdoor use, the coloring technique plays a big role in durability. Integral colors, which are mixed directly into the concrete, or dry-shake color hardeners are the most UV-stable options. Tim Seay from Decorative Concrete of Virginia explains:

"I actually think this is the better way to color concrete… This is called broadcasting color hardener. Color hardener is a blend of sand, Portland cement, and pigment."

This method not only enhances surface density but also ensures vibrant, long-lasting color.

Stamped concrete patterns typically cost $8–$12 per square foot for basic designs, while more intricate, multi-color options start at $18 per square foot. Compared to individual pavers, which can reach $20 per square foot, stamped concrete is about 25% less expensive. With proper sealing using UV-stable topcoats like polyaspartic or solvent-based acrylics, stamped surfaces can resist fading and chemical wear for years.

For practical design, avoid deep grooves that could make patio furniture unstable. Scott Cohen also advises choosing lighter shades, like sand or coral, for pool decks to keep surfaces cooler. White concrete infused with titanium dioxide can even lower surface temperatures by up to 20°. These thoughtful design choices not only improve aesthetics but also enhance usability in outdoor spaces.

Companies like Atlas Concrete Coatings take it a step further by applying UV-resistant polyurea systems over stamped concrete. These coatings provide long-lasting protection against fading and maintain slip resistance, even in areas exposed to constant sunlight. This ensures a blend of authentic texture and outdoor durability that stands the test of time.

5. Garage-to-Patio Transitions

Unified Coatings for Indoor-Outdoor Flow

Creating a smooth transition from your garage to your patio calls for coatings that work equally well indoors and outdoors. Polyurea systems stand out here – they’re four times stronger and 98% more flexible than standard epoxy, making them resistant to cracks caused by thermal expansion and contraction. Unlike epoxy, which can yellow and break down under sunlight, polyurea offers 100% UV stability, ensuring the transition area remains vibrant and fade-free even in direct sunlight.

Strength is just one part of the equation; design consistency is equally important. Matching the color scheme between your garage and patio creates a unified look. Decorative vinyl flakes are a great option – they can be custom-blended to tie the two spaces together. Neutral tones like beige or sand are particularly effective. They not only reflect sunlight to keep surfaces cooler but also enhance visual harmony between the areas.

For areas that endure both vehicle and foot traffic, durability is key. Choose coatings with a PSI rating of at least 5,000 to ensure they can handle the pressure. Proper preparation, like diamond grinding, is essential to open the pores of the surface, allowing the base coat to form a permanent bond that resists moisture and peeling. Atlas Concrete Coatings specializes in UV-resistant polyurea systems tailored for these high-traffic zones, offering walk-on readiness in just 24 hours. This ensures a seamless transition from the ruggedness of the garage to the elegance of the patio.

Safety also plays a critical role. Adding a slip-resistant texture is a smart move, especially in areas prone to rain or moisture. The coating should strike a balance – comfortable enough for bare feet on the patio while tough enough to handle tire pressure in the garage.

6. Textured Non-Slip Surfaces

Polyaspartic Coatings with Anti-Slip Additives

Polyaspartic coatings offer reliable UV protection and excellent traction, making them a great choice for outdoor spaces. These coatings boast an impressive adhesion strength of 1,341 PSI – more than three times the standard. Unlike traditional epoxy, which tends to yellow and break down when exposed to the elements, polyaspartic coatings retain their color and durability for 15 to 20 years.

The secret to creating a slip-resistant surface lies in the topcoat. By incorporating clear aggregates like aluminum oxide particles, polypropylene beads, or sand into the final layer, these coatings enhance grip without sacrificing visual appeal. When properly textured, they exceed national safety standards, achieving a friction coefficient well above 0.42. This combination of safety and durability makes them ideal for outdoor settings.

At Atlas Concrete Coatings, our polyaspartic systems are specifically designed for outdoor use. They provide a comfortable surface for bare feet while ensuring the necessary grip around water features. For the best results, surfaces should be mechanically ground to a 150-grit profile to ensure a permanent bond. A moisture vapor test is also essential; if readings exceed 3 lbs per 1,000 sq. ft. over 24 hours, a mitigation layer is required.

Keeping these surfaces in top condition is simple. Use pH-neutral cleaners to maintain the anti-slip texture and protect against UV damage, ensuring the coating remains intact without fading or peeling.

Conclusion

UV-resistant coatings elevate outdoor concrete spaces by making them more durable and visually appealing, even under harsh sunlight, shifting temperatures, and daily wear. While traditional epoxy coatings often fall short in outdoor settings, polyaspartic coatings stand out for their ability to maintain both their appearance and structural strength for 15–20 years.

These coatings go beyond just durability. They offer a wide range of design options, from rustic stone-like textures to sleek, modern finishes, all while protecting against moisture, chemical exposure, and the damaging effects of freeze–thaw cycles. For added safety, slip-resistant additives can be included, making areas like pool decks and patios safer by reducing the risk of slipping on wet surfaces.

Industry professionals emphasize the advantages of polyaspartic coatings:

"Polyaspartic is superior to epoxy resin in that it will not yellow from UV light/sun exposure, it will better absorb the contractions/expansions of the underlying concrete, and it will hold up for longer." – Everlast Concrete Coatings

However, achieving these results depends heavily on proper installation. Key steps such as thorough surface preparation and moisture testing – factors that account for 80% of a coating’s success – are crucial. When professionally applied, these coatings create a permanent bond with the concrete, ensuring they withstand even the most extreme conditions without delaminating.

FAQs

What makes polyaspartic coatings a better choice than epoxy for outdoor concrete surfaces?

Polyaspartic coatings are a great option for outdoor concrete areas thanks to their strong UV resistance, which helps keep surfaces from fading or yellowing over time. They also cure faster than traditional epoxy, which means less downtime during installation. On top of that, these coatings are tough, resistant to cracking, and built to handle harsh weather conditions – perfect for spaces like patios, pool decks, and other outdoor spots.

How can cool-toned concrete designs make outdoor spaces more comfortable?

Cool-toned concrete designs are a game-changer for outdoor comfort. By reflecting more sunlight and absorbing less heat, these surfaces can lower temperatures by up to 50°F. This makes spaces like patios and pool decks not only safer but also far more pleasant to use during scorching weather.

Incorporating UV-resistant coatings and opting for lighter color tones can enhance both the style and functionality of your outdoor areas, keeping them cooler and more comfortable, even under the blazing sun.

How can I create a smooth transition between my garage and patio with concrete coatings?

To create a smooth and visually appealing transition between your garage and patio using concrete coatings, start by selecting UV-resistant, durable options that can handle outdoor conditions like sunlight and weather. Polyurea-based coatings are an excellent choice because they resist impacts, abrasions, and fading, while also curing quickly to minimize downtime.

For a unified appearance, aim to match the color and texture of the coatings across both spaces. This will create a seamless flow from one area to the next. To enhance safety, especially in areas exposed to moisture, consider adding slip-resistant materials like silica sand. Don’t overlook the importance of surface preparation – cleaning, repairing any damage, and etching the concrete are essential steps to ensure the coating adheres properly and delivers a flawless finish.

By prioritizing durable materials, consistent design elements, and thorough preparation, you can create a long-lasting and visually cohesive connection between your garage and patio.